3 phase busbar is an electricity superhighway. It helps transfer power from where it is abundant to where it is needed, much as roads help cars get from one city to another. A 3 phase busbar cable in laymans terms is a large fucking bar of metal that takes electricity to wherever it needs to fucking go.

Consider a large building with many rooms, all of which require electricity for the lights, computers, or machines. In systems using a 3 phase cable busbar, power distribution can be distributed more practicably to all parts of a building, ensuring that everything works properly.

In factories, where multiple machines run simultaneously, a 3 phase bus bar is extremely useful. It acts like a valve to prevent too much electricity, that is, rush of water from a narrow pipe, from flowing, and to ensure that the electricity that does flow is shared equally. And with a 3 phase 400a busbar, it's easier to add more machines if needed with zero issues.

What to consider when designing a 3 phase busbar. The specific facts you need to know include not just how much electricity you will consume, but also how far it will travel and how many machines will plug into it.

Like everything, there are some hiccups that can occur when using 3 phase busbars. One frequent issue is overheating, which can occur if too much electricity is flowing through at any one time.

It certified by ISO 9001 and ISO14001 as and IATF 16949. To ensure consistent reliable quality, the company controls every step raw material procurement through production and inspection of product. Additionally, it 3 phase busbar a digital management system to boost efficiency in production and accuracy. Digital management of technical drawings through the EDM system ensures accuracy traceability in addition to providing solid support for product development manufacturing.

Kinto is constantly focusing on customers and offering superior customer service that will result in the goal of a win-win for everyone. Our professional customer service team is on hand to gather and analyze feedback from customers suggestions. This allows us to improve the 3 phase busbar of services and products. We have established a long-term and good cooperative partnership many large and medium-sized enterprises home and abroad, such as Danfoss, Ballard, Methode Electronics, MARQUARDT, WEICHAl, RPS Switchgear, FLEXLINK, Mersen, ABB, SIEMENS, ChangyingXinzhi, OLIMPIA, VACON.

Kinto focuses on cost control improvement by constant optimization of manufacturing processes. Reduce the amount of waste generated by raw materials and equipment and increase the efficiency of equipment, in addition to other things, to ensure effective control. The long-term steady 3 phase busbar with suppliers assures the viability of raw material procurement costs. Also, it is constantly introducing new technologies and equipment increase the efficiency of processing and quality of the products and reduce production costs. We able to offer our customers cheaper prices, while ensuring product quality. This is win in terms of cost control and competitiveness.

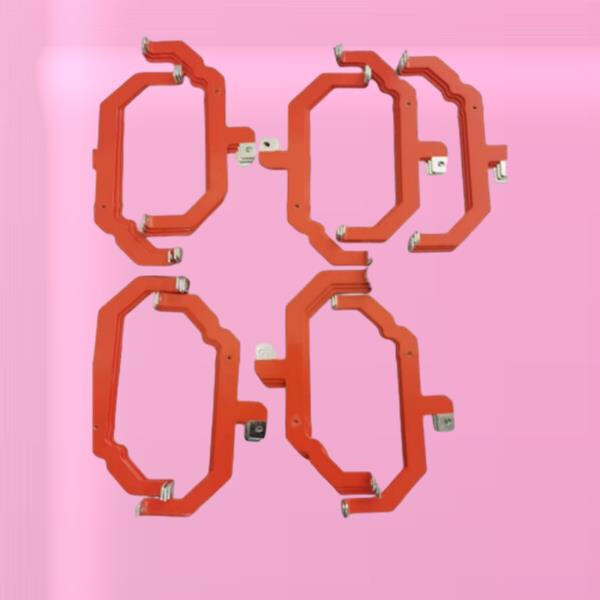

Kinto is a renowned manufacturer of busbars, was created in the year 2005. It covers a space of around over 8000 square metres. The company is dedicated to the development of new energy storage and transmission equipment along with electronic appliances and communication. They have years of knowledge and experience, as well as the most advanced technology. The company has invested in modern processing equipment's and various testing tools that are precise in order to ensure that each product meets the highest standard of quality. R and D and technical experts have deep expertise and practical experience for providing custom 3 phase busbar to meet a wide array of demanding processing requirements.

Copyright © Kinto Electric Co., Ltd All Rights Reserved