I am sure you might be aware of one thing — an electric busbar. Although this might sound somewhat convoluted or pretentious, the fact is that it plays a crucial role in many electrical systems which are widely available nowadays. The busbars are vital for transferring power from one part of a system to another. These are essentially called power lines, and if we use roads analogy they will be similar to highways for electricity traveling through different points so that energy can flow without any interruptions.

Electrical busbars are simply long strips of conductive metal that can transmit electricity. Ordinarily, these busbars will be constructed from such materials as copper or aluminum which are both good conductors of electricity. Busbars are used in numerous areas such as power plants, electrical substations or even your own house. This is very important as the busbars help conduct electricity in a more direct and quicker way than regular wiring. Standard wiring is not only bulky, but it may be incapable of managing the load demand for power. This can create problems. By substituting these electrical busbars, the journey of electric power is made more holistic with fewer obstacles thus less energy lost transferring from point to another.

One of the good side benefits is that electrical busbars will save a lot on energy, which could also result in some great savings to your electric bill! As electricity moves around more effectively due to the use of busbars, this equates with hugely reduced energy loss. Not only that in some serious conditions, but busbars can also prevent power outages occurring by continually keeping together two parts of its electrical systems. The less energy loss you have, the more efficient your entire system can operate and be relied on for minimal outages or blackouts. Due to which you face no power loss of any kind in your life or at work.

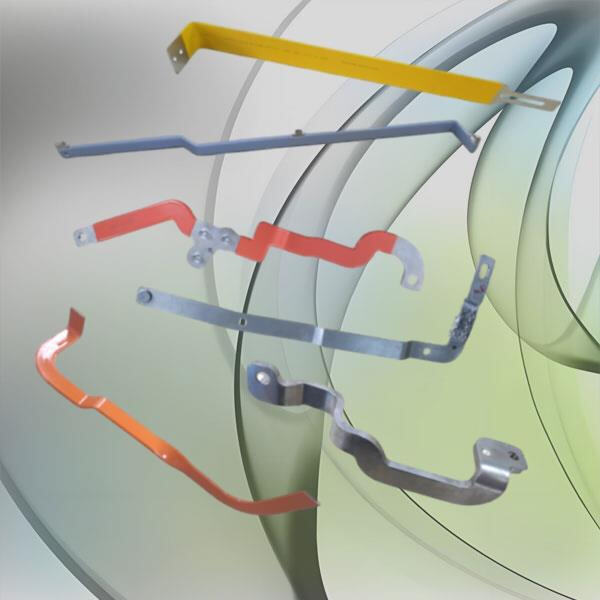

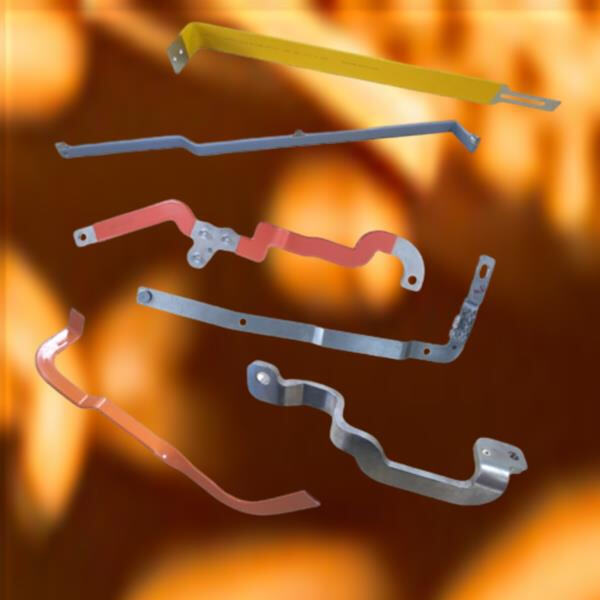

Electrical Busbar Types: Please note that one of the following types of electrical busbars must be used depending on where each goes. There are models of busbar that tie directly into particular types of electrical systems and others like the current snow model, which is more generic and can be used in a variety ways. The rigid busbar is one of the most common types of electrical busbarsancers. While you might not see many things that look like busbars right away, the rigid with which their made from (usually copper or aluminum) will isolate them because they are stiff and do not easily bend. They work very well for stationary capacities that require the busbar not to move. The other is the flexible busbars. The busbars themselves are typically low-profile (it might include thin metal foil with insulation) streams that carry the power from point to point. This design allows them to bend and flex, which can be useful in situations that require movement like machinery or vibrating equipment.

So, if you want your electrical busbars to be in good condition and work efficiently then it is necessary to monitor them periodically. Moving time the connections can become, loose or corroded which would affect how effectively power flowed through those pipes to every electrical thing in your old girl. Insecure connections may cause issues such as: lack of energy, or even the complete power failure. Along the way, if you keep an eye on your busbar connections and maintain them efficiently,you can have such issues discovered before they firmly establish into a worrisome problem. This is to help keep your electrical system at optimal performance.

Busbar technology and design are also getting improved in the next level as our technology grows. Exploration of novel materials is one dynamic recent innovation in busbar technologies. Such advanced, high-electrical-conductivity composite materials are currently being research by scientists. These new busbars could potentially be lighter, more economical and also in some applications electrically superior to conventional thick-copper or aluminum alternatives. In addition, busbar design is also advancing. B Call to ActionCreate busbars available in a wide range of different shapes and sizes, providing considerable reduction in energy loss leading to enhanced efficiency for the electrical systems they are employed in.

Kinto is top manufacturer of busbars, was founded in the year 2005. It covers an area of more than 8000 square meters. Kinto is committed to the development of new energy storage and transmission technologies along electronic appliances and communication. Kinto has a wealth of experience and industry-leading technology. Kinto introduced cutting-edge processing equipment's and a selection high-quality testing equipment to ensure that every product meets the highest Electrical Busbar requirements. The R and D team and technical team have deep knowledge and experience in delivering custom solutions a range of processing needs that are complex.

Kinto is focused on cost control and improvement through continual optimization production processes. Reduce waste in raw materials and equipment, and improve the utilization of equipment, in addition to other methods, to attain an effective control. The long-term and steady cooperation with suppliers guarantees competitiveness of procurement costs for raw materials. In addition, it actively introduces advanced production Electrical Busbar equipment to improve production efficiency and quality and reduce production costs. This allows us give customers affordable prices while still ensuring high-quality, and to achieve an ideal balance between cost control market competitiveness.

Kinto is constantly focusing on customers and offering superior customer service that will result in the goal of a win-win for everyone. Our professional customer service team is on hand to gather and analyze feedback from customers suggestions. This allows us to improve the Electrical Busbar of services and products. We have established a long-term and good cooperative partnership many large and medium-sized enterprises home and abroad, such as Danfoss, Ballard, Methode Electronics, MARQUARDT, WEICHAl, RPS Switchgear, FLEXLINK, Mersen, ABB, SIEMENS, ChangyingXinzhi, OLIMPIA, VACON.

It certified by ISO 9001 and ISO14001 as and IATF 16949. To ensure consistent reliable quality, the company controls every step raw material procurement through production and inspection of product. Additionally, it Electrical Busbar a digital management system to boost efficiency in production and accuracy. Digital management of technical drawings through the EDM system ensures accuracy traceability in addition to providing solid support for product development manufacturing.

Copyright © Kinto Electric Co., Ltd All Rights Reserved