Bus bars for batteries are critical in a vehicular electrical system such as a bus. They help wire together a lot of batteries so that they can function as a group to power the vehicle. The bus bars need to be the right size and installed properly to ensure everything runs well. So what are busbar in battery pack— and how can you care for them?

Battery bus bars serve as a bridge, allowing electricity to flow between various batteries. They test for all of the batteries to ensure that all are connected properly to send the power to where it’s needed in the bus. No battery bus bars, and the batteries wouldn’t cooperate and the vehicle wouldn’t move.

Batteries are connected in two ways by kinto battery bus bars: in series or in parallel. In a series connection of batteries, the positive terminal of one battery connects to the negative of the other. This totals the voltage of all of the batteries. When battery pack busbar are connected in parallel, the positive sides are connected together and the negative sides are connected together. This totals the battery capacity.

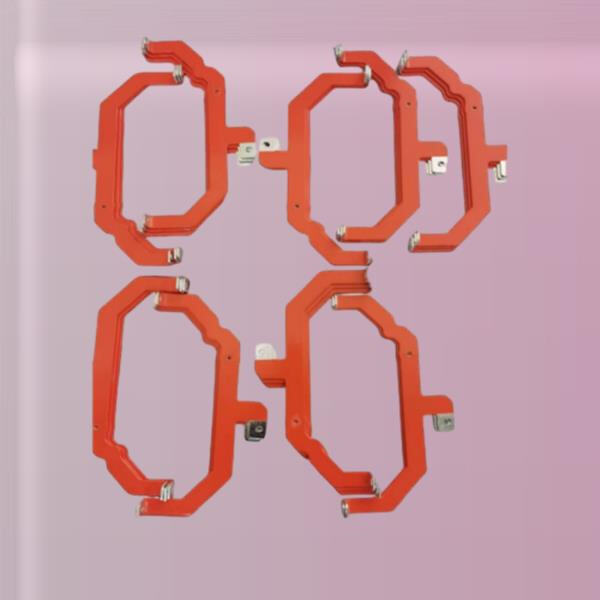

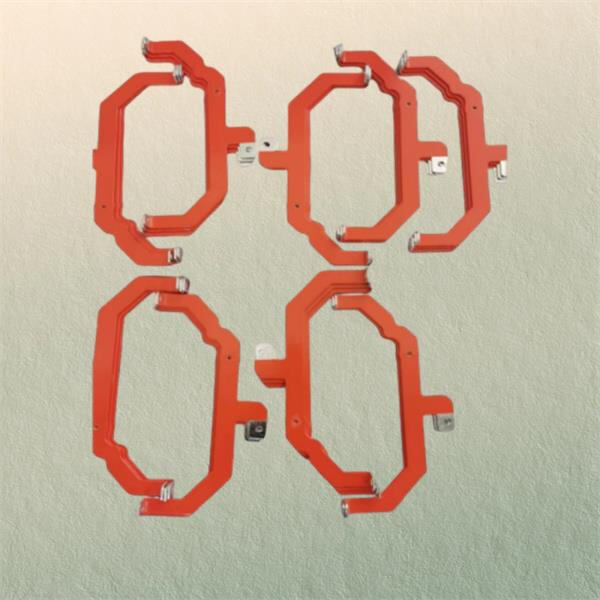

Big thing is to make sure the kinto battery bank busbar size is correct. If they are too small, they might not be able to carry all the electricity passing through them and could be damaged. If they are, that can take up a lot of space or could cost more than they should. It’s also important to install the bus bars properly so they make good connection between the batteries.

The kinto battery terminal bus bar can be constructed in different materials, such as copper or aluminum. It is fantastic at conducting electricity, and we use it because it is capable of transporting a great deal of power without becoming too hot. Aluminum is nice, too, because it is lighter and cheaper than copper. Each material has its advantages, so it's just a matter of choosing that which works best for the vehicle.

If something goes wrong with the battery bus bars in a vehicle, there’s some things to check. Be sure the bus bars are shiny and not rusty, as rust can prevent electricity from traveling. Also, see if the bus bars are firmly connected to the batteries. Tighten any loose connections. By regularly maintaining the battery bus bars, you can avoid issues and keep your vehicle running without a hitch.

Kinto is focused on cost management improvement through continual optimization of manufacturing processes. Reduce the amount of waste generated by equipment and raw materials and enhance the efficiency of equipment, among other strategies, in order to achieve effective control. Long-term and stable cooperative relations with suppliers assures viability of procurement costs for raw materials. In addition, it constantly introducing new production technologies and equipment that improves production efficiency quality and reduce production costs. This helps us offer our customers better affordable prices while maintaining product quality an optimal Battery bus bar of cost control and market competitiveness.

Kinto is a renowned manufacturer of busbars, was created in the year 2005. It covers a space of around over 8000 square metres. The company is dedicated to the development of new energy storage and transmission equipment along with electronic appliances and communication. They have years of knowledge and experience, as well as the most advanced technology. The company has invested in modern processing equipment's and various testing tools that are precise in order to ensure that each product meets the highest standard of quality. R and D and technical experts have deep expertise and practical experience for providing custom Battery bus bar to meet a wide array of demanding processing requirements.

Kinto always prioritizes needs of its customers and offers exceptional customer service to create a win-win situation. A professional customer service team is hand to Battery bus bar and analyze customer feedback and suggestions. This helps enhance the quality of our services and products. We established a long-term and good cooperative partnership with many large and medium-sized enterprises at home and abroad, such Danfoss, Ballard, Methode Electronics, MARQUARDT, WEICHAl, RPS Switchgear, FLEXLINK, Mersen, ABB, SIEMENS, ChangyingXinzhi, OLIMPIA, VACON.

It is certified by ISO 9001 ISO14001 as and IATF 16949. The company is able control each connection from the procurement of raw materials through production to final product inspection to ensure stable reliable quality of product. Furthermore, the Battery bus bar implements a management system is digital to boost efficiency in production and ensure accuracy. The management of technical drawings digitally via EDM system offers transparency and precision in addition to providing solid support for development and manufacturing.

Copyright © Kinto Electric Co., Ltd All Rights Reserved