Are you a hobbyist who loves to fiddle with electronics kits and build circuits? If you have, then chances are that you realise how important it is for all the pieces to be kept connected properly. Join Link Everything Together Properly and Your Projects Will Scale Better & You'll Have More Fun! Bonding busbars are a solid way to ensure all your electrical connections stay tight, secure & safe.

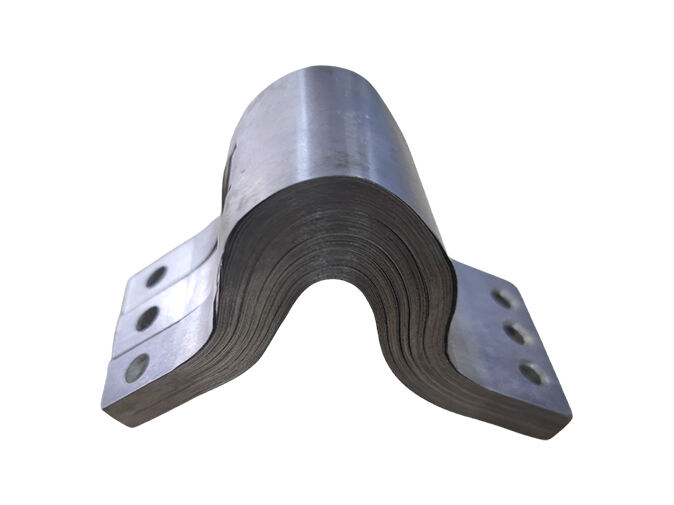

A bonding busbar is a metal strip for connecting different electrical elements. Small items such as copper wires, to large components, like transformers can be connected. With the use of bonding busbars, you will be able to work with your electrical devices and this will help make your experience easier. So that the projects you make will run smoothly and be long-lasting.

In the electrical products ', it must be strong and safe to generates a free flow of electricity properly. Bonding busbars have a large impact on making these systems better by improving the connections between all of the various components. Those near perfect connections allow for electricity to flow easily; meaning less resistance.

The less resistance the better - which in turn makes your entire electrical system more reliable. After all, everything can only work together properly under the condition that electricity is undoubtedly unrestricted. This will be slightly an overhead for small projects but is a life-saver when you have many moving parts in your project and need everything to work together, (by play nice!)

The busbars are manufactured in such a way that they can be connected with multiple electric parts forming strong links. This strong link is what keeps you insulated from the dangerous electric currents that could take place when there's an issue inside of electrical flow. Employ bonding busbars for peace of mind that your system is built to last.

Bonding busbars are intended to be used in projects where you need high performance from your devices. So that there is good conductivity between the various parts. If everything is connected neatly and efficiently, your devices can perform optimally as well respond quickly which in turn would increase the life of systems.

Bonding busbars form a very low resistance path which means reduction of stray electric currents. Which is important, as stray currents can produce electrical shocks or other hazardous conditions. Bonding busbars help to reduce those risks, which also makes your electrical work much more safe.

Kinto is focused on cost control bonding busbar through continual optimization of production processes. Reduce the waste of equipment and raw materials and optimize use of equipment, among other measures, to achieve effective control. The long-term and steady cooperation suppliers assure the viability of procurement costs for raw materials. The company also continuously introduces new production technologies and equipment in order to improve the quality and efficiency of processing products, and thereby reduce production costs. We can offer customers cheaper prices, whilst ensuring the highest quality. This is a win-win situation for cost control competitiveness.

It is certified through ISO 9001 and ISO14001 as along with IATF 16949. The company strictly control every link raw material procurement through production to final product inspection to ensure stable reliable quality of the product. In addition, it implements a digital bonding busbar system boost efficiency production and precision. The management technical drawings digitally with the EDM system ensures highest level of traceability and accuracy in addition to providing solid support for product development and manufacturing.

Kinto is a leading busbar manufacturer founded in 2005 and covers an area of 8000 square metres and is committed to development of new energy storage, transmission and distribution products, electronic appliances and communications using the most advanced technology the market and extensive production experience. Kinto has invested in cutting-edge processing equipment's as well an array of high-quality testing instruments which ensure that every product is of the highest standard of quality. The R and D team the technical team have extensive knowledge and expertise in delivering tailored solutions a variety of bonding busbar processing requirements.

Kinto always puts customer first and offers excellent customer service in order to achieve win-win growth. Our customer service department highly skilled and is on hand to collect and analyze feedback from customers suggestions. This allows us to improve our products and bonding busbar. We have established a long-term good cooperative partnership with many large medium-sized enterprises at home and abroad, such as Danfoss, Ballard, Methode Electronics, MARQUARDT, WEICHAl, RPS Switchgear, FLEXLINK, Mersen, ABB, SIEMENS, ChangyingXinzhi, OLIMPIA, VACON.

Copyright © Kinto Electric Co., Ltd All Rights Reserved