Have you ever wondered how electricity gets to your house or school? It’s a fascinating process! Bus bar copper has been & will continue to be a huge part of this journey.

Bus bar copper: Bus bar we often need to move electricity from one place selling a small home using long metal. Think of it as the highway for electricity! Therefore, the way a car must have a road to drive on, electricity requires bus bar copper in order to go were it needs too. We would have a lot of difficulty getting the electricity to our homes, schools and businesses without bus bar copper.

Description:Available in the whole range of conductive alloys for bus bar copper (the only exception probably being oxygen free BeCu). It lets the electricity go through it ever so easily. This is a big deal because lots of places, such as factories or tall buildings need tons and tons of electricity to run their machines (you know in factories) and lights. If the wires that carried 110 volts electricity into it were too small than they could over heat, dangerously so. Good news is that bus bar copper can withstand a lot of electricity without heating up and causing energy loss, so it offers an efficient use case.

Most of that energy, when electricity flows through wire can lost as heat didn't you know? This is why it comes out of the box with materials that have very high electrical conductivites. This is one of the best materials to use for IE bus bar copper! It is doesn't expend much energy at all,meaning more can be directed towards the important things that we cannot and should not do without-like lighting our homes or charging up devices. Using bus bar copper ensures we are helping to conserve energy.

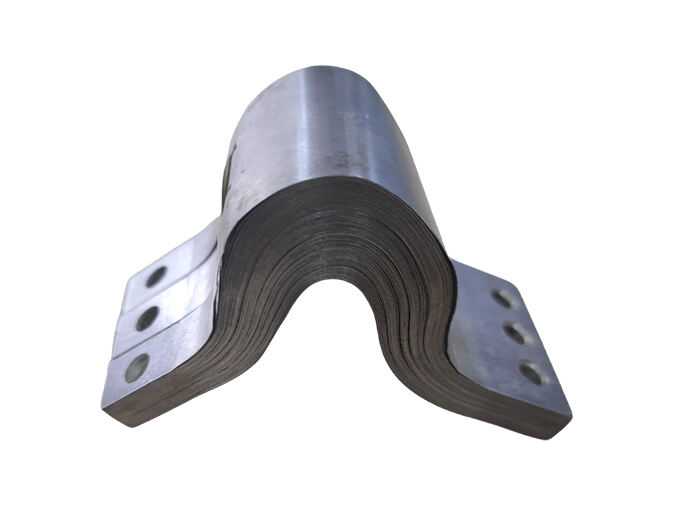

Attributes of Bus Bar Copper - Thankfully, bus bar copper is also quite versatile and able to be manufactured in lots of shapes and sizes! The wide-angle design also make the drop ceiling mount suitable for different applications. This could mean being molded into little cubes to fit it in tight spots, or making a flat slab that aligns closer with the design of some devices. Bus bar copper can also similarly be coated with a variety of different materials to help it last longer or simply make it more appropriate for use in varied environments. Its flexibility also means it is ideal for a wide variety of electronic applications.

If it has something to do with electricity, we need some high-quality materials — but these components must be strong and longlasting. The last thing you would want is for the wires to come loose or degrade, and then all of a sudden no power reaches your appliance. Fortunately, bus-bar like copper is very durable and will last a long time. Additionally, it hascausing weathering properties such as high temperature and humidity resistance making this perfect foroptimal fo electrical connections in a multitude of different atmospheric settings.

The company always puts quality of the product the first place, it's accredited through ISO 9001, ISO14001, IATF 16949, and various other certifications. To ensure consistent and reliable quality, the company controls every step procurement of raw materials to production until product inspection. It also adopts a digital management system to improve the efficiency of production and improve bus bar copper. The digital management technical drawings with the EDM system ensures the accuracy and reliability of drawings. It also provides solid support for the development of products and production.

Kinto is focused on cost control continuous improvement of manufacturing processes. Reduce the amount of waste generated raw materials and equipment, and enhance the efficiency of equipment, in addition to other things, to ensure efficient control. A long-term, stable and reliable relationship with suppliers will ensure the efficiency in procurement of raw materials. We also constantly introduce bus bar copper production methods equipment to enhance the efficiency and quality of processing of the products decrease production costs. Our customers can enjoy better prices, while maintaining product quality. This is a win in terms cost control and competitiveness.

Kinto is a top busbar producer bus bar copper in 2005 covering 8000 square meters is committed to the development of new energy storage, transmission and distribution products, electronic appliances and communications featuring the latest technology and a wealth of production experience. Kinto has introduced latest processing equipment's and a variety of high-quality testing equipment to ensure that every product is in line with highest standards of quality requirements. The R and D team technical staff have extensive expertise and experience in providing customized solutions for a wide range complex processing requirement.

Kinto is constantly focusing on customers and offering superior customer service that will result in the goal of a win-win for everyone. Our professional customer service team is on hand to gather and analyze feedback from customers suggestions. This allows us to improve the bus bar copper of services and products. We have established a long-term and good cooperative partnership many large and medium-sized enterprises home and abroad, such as Danfoss, Ballard, Methode Electronics, MARQUARDT, WEICHAl, RPS Switchgear, FLEXLINK, Mersen, ABB, SIEMENS, ChangyingXinzhi, OLIMPIA, VACON.

Copyright © Kinto Electric Co., Ltd All Rights Reserved