For good reason, bus bars play a vital role in electrical systems. They assist in electrifying the various segments of a building. Bus bars are very similar to the roads that bring the electricity to where they need to go. Let us dig deeper into what bus bars is and its importance in electrical systems busbar 300a

They are crucial for the safe and efficient dispersal of electricity. Thus, without bus bars, electricity would not flow smoothly, leading to power outages and electrical malfunctions. This helps electricians to regulate the movement of electricity through a building using bus bars. This helps control and monitor the flow of electricity busbar 250a

Bus Bars used in building with regards to need. Some are called bus bars, while others are flat. Copper and aluminum are the most common metals used for bus bars, although brass or silver can also be used. How much electricity needs to be supplied and how much space is available for installation will determine the type and material of the bus bar used by the electricians.

Advantages of Using Bus Bars in Electrical Panels They minimize the required wiring in such configuration, as using a few wires for the control and diagnosis of the system makes the installation more visually attractive. For electricity, bus bars also offer a more stable link, helping to decrease the possibility of power outages. On top of that, bus bars are easier to install as well as maintain, which can save time and money for both electricians as well as building owners.

Regular maintaining of bus bar is very crucial to maintain their safety and performance.【FAQ series】 Both of these needs to be monitored by electricians frequently. They also need to ensure that the bus bars are clean and clear from dust or debris, which can inhibit the flow of electricity. So you should also follow the safety procedures when working with bus bars, such as wearing the protective gear, disconnecting the power before doing any maintenance work, etc.

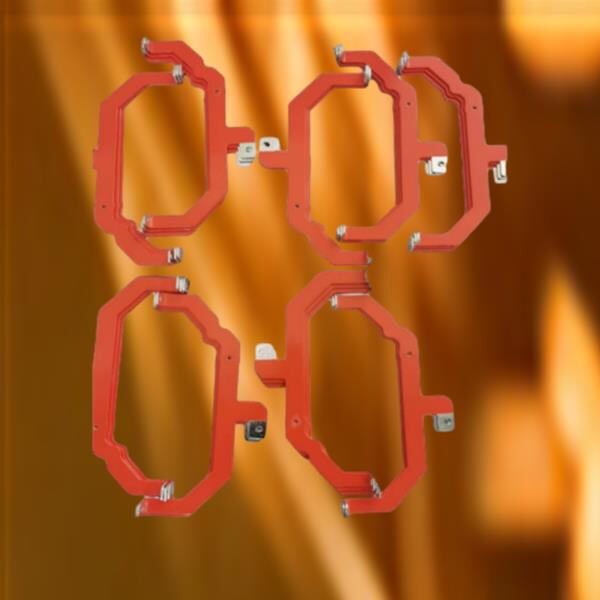

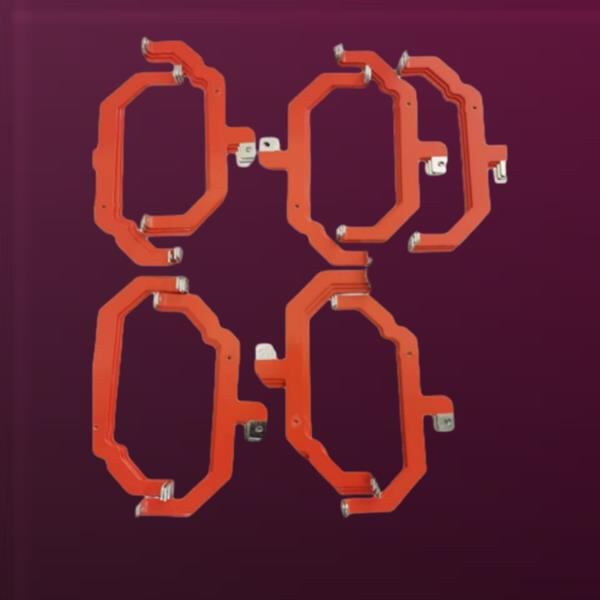

Kinto is renowned manufacturer busbars, was established in 2005. It covers an area of 8000 square meters. The company is dedicated to the creation innovative energy storage and transmission products addition to electronic appliances and communication. They have years of knowledge and expertise, as well as industry-leading technology. Kinto has developed advanced processing equipment's a variety of testing tools that are precise to ensure that every product meets highest standards of quality Bus bar in electrical. The R and D team and technical team have deep knowledge and experience in delivering custom solutions to a range of complex processing requirements.

Kinto always places the customer first offers exceptional customer service in order to create a win-win situation. Kinto has a Bus bar in electrical customer service department will constantly collect customer opinions well as suggestions to improve the quality of services products. We have established a long-term and good cooperative partnership with many large medium-sized enterprises at home and abroad, such as Danfoss, Ballard, Methode Electronics, MARQUARDT, WEICHAl, RPS Switchgear, FLEXLINK, Mersen, ABB, SIEMENS, ChangyingXinzhi, OLIMPIA, VACON.

It is accredited through ISO 9001 and ISO14001 along with IATF 16949. To ensure consistency and reliability quality, the company oversees each step of the process, from procurement of raw materials to production, to inspection products. The company also implements a digital management system boost production efficiency and accuracy. The digital administration technical drawings using the EDM system ensures the accuracy and reliability drawings. It also provides solid Bus bar in electrical for product development and production.

Kinto focuses on cost control improvement through continual optimization of manufacturing processes. Reduce the waste of raw materials and equipment improve the utilization of equipment, in addition to other methods, to attain efficient control. The long-term and steady cooperation with suppliers guarantees competitiveness of raw material procurement costs. It also actively introduces new equipment and production techniques enhance the quality and efficiency of processing of products, which in turn reduce costs of production. These measures enable us to offer our customers better competitive prices while ensuring product high-quality and achieve an optimal balance of cost Bus bar in electrical and market competitiveness.

Copyright © Kinto Electric Co., Ltd All Rights Reserved