We all need the proper fuel to power some of which we may use at work - actual food for yourself, gas for your car; electricity so that you can charge our telephones and watch everyone's favorite (but infuriating) TV. But how can we control that it is a fluid system and energy are used efficiently? Where the busbar CTs steps in, acting as the foundation of energy monitoring systems.

These busbar CTs offer a range of advantages in the context of monitoring energy across an entire building. At the end of the day, a busbar is employed to determine which electric current goes through it so as to be told just how much energy there may be each process inside an individual constructing. Businesses can reduce their electricity bills which also saves money and is much kinder to the carbon footprint we leave on our planet.

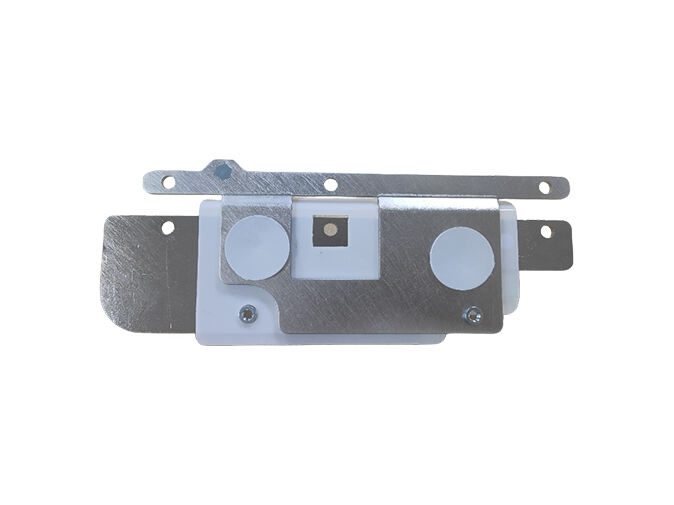

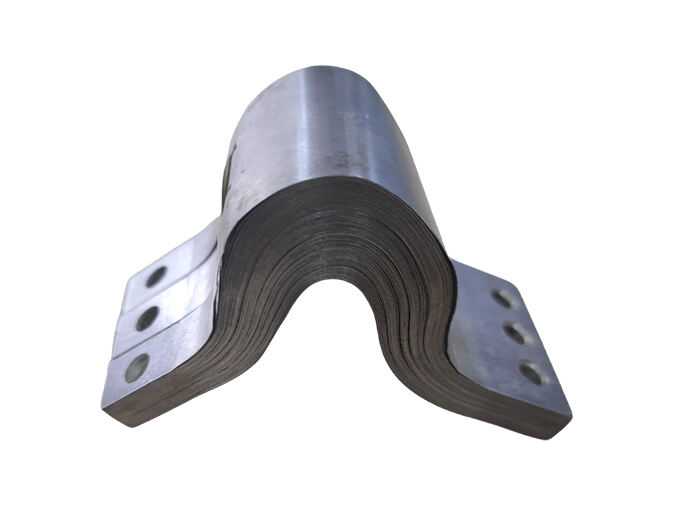

Busbar CTs read the current that flows through a bus bar, which is just copper( or in some places aluminum ) stripe used for electric power transfer reactions at shorter distances. The busbar CT clamp on the Bus bar and measure actual current flow, send it data to monitoring system for futher analyse, logging.

The busbar CT is an essential solution for monitoring Power consumption in buildings. So, this means, people may actually understand where the electrical energy is consumed and they can lay out strategies on how to optimize their systems better resulting in more savings which achieves a sustainable future. As an example,, if we note a site using even more electrical energy than required owning assists motivate corrections to reduce the electricity being made use of by this certain body; therefore decreasing make usage associated with electric expenses too.

One of the standout features is that they are universal in application and go from any busbar CTs to fit. Lithium iron phosphate (LFP) batteries, advanced energy storage devices can be applied in high-reliability market segments like factories, data centers and commercial buildings or for specific renewable applications to solar panels and wind turbines. Or, in the case of direct metering at a busbar level CTs are used to provide simple and effective logging (energy production or use) alarms/alerts as well ensure systems remain online.

This is in the line of energy conservation needed across all nations and therefore busbar CTs will be taken over gradually. When companies are under pressure to reduce their carbon footprints and optimize energy use, busbar CTs contribute significantly towards this goal.

Summary - Busbar CTs lead energy measuring instrument saving the cost and sustainability. This is measured as readings by current, i.e. Amps across a busbar and collecting it to display at the other end for now respective analysis. As energy efficiency concern is on the rise throughout world, busbar CTs are expected to get deployed in majority applications. Note: English (Automatic). Their devices are flexible, they can be employed by multiple industry verticals. Integration of busbar CTs in your electrical distribution system is a giant leap towards the modern energy-efficient tomorrow.

Kinto is focused on cost management improvement through continual optimization of manufacturing processes. Reduce the amount of waste generated by equipment and raw materials and enhance the efficiency of equipment, among other strategies, in order to achieve effective control. Long-term and stable cooperative relations with suppliers assures viability of procurement costs for raw materials. In addition, it constantly introducing new production technologies and equipment that improves production efficiency quality and reduce production costs. This helps us offer our customers better affordable prices while maintaining product quality an optimal busbar ct of cost control and market competitiveness.

Kinto is constantly focusing on customers and offering superior customer service that will result in the goal of a win-win for everyone. Our professional customer service team is on hand to gather and analyze feedback from customers suggestions. This allows us to improve the busbar ct of services and products. We have established a long-term and good cooperative partnership many large and medium-sized enterprises home and abroad, such as Danfoss, Ballard, Methode Electronics, MARQUARDT, WEICHAl, RPS Switchgear, FLEXLINK, Mersen, ABB, SIEMENS, ChangyingXinzhi, OLIMPIA, VACON.

It is accredited through ISO 9001 and ISO14001 as in addition to IATF 16949. To ensure consistent secure quality, the firm controls every stage of production, from procurement of raw materials production until product inspection. In addition, it implements a digital management system boost production efficiency and ensure accuracy. Digital management of technical drawings using the EDM system gives precision traceability along with strong support for product busbar ct manufacturing.

Kinto is top manufacturer of busbars, was founded in the year 2005. It covers an area of more than 8000 square meters. Kinto is committed to the development of new energy storage and transmission technologies along electronic appliances and communication. Kinto has a wealth of experience and industry-leading technology. Kinto introduced cutting-edge processing equipment's and a selection high-quality testing equipment to ensure that every product meets the highest busbar ct requirements. The R and D team and technical team have deep knowledge and experience in delivering custom solutions a range of processing needs that are complex.

Copyright © Kinto Electric Co., Ltd All Rights Reserved