Discovering the Magic Behind Busbar DC Power Distribution

Have you ever considered the amazing technology of busbar dc that is changing how cities and households all over the world are powered? What Is Busbar Dc? - The State-Of-The-Art Electrical Distribution Method with a long list of Advantages In this article, we will discuss more complex layering of busbar dc and why they are even implemented at such a growing rate.

Revealing the benefits of Busbar DC Power Distribution

We can act like we have super power (electricity) that run machines and light our rooms. But what most fail to realize is, with electrical power if not managed properly can get wasted. This is exactly where the busbar dc comes to our rescue.

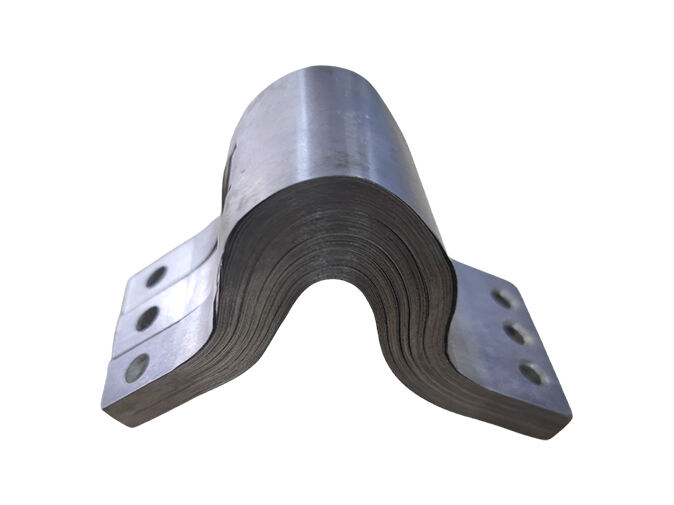

Busbar dc is an exclusive type of electrical power distribution that makes use of a flat metal bar, usually copper or aluminum) and also kept insulated to give dependable performance. Busbar dc allows power to be transported over distances with minimal loss, resulting in a much larger fraction of the electrical generation being consumed where it is actually needed.

Advantages of Busbar dc Systems over Conventional Electrical Power Distribution systems These are high efficiency systems designed to reduce electrical power loss even further. The reason for this is the lower resistance of busbar dc to traditional designs, thus allowing a much smoother path for electricity.

Considering the dc side, busbar systems are highly adaptable and can be engineered for a variety of applications. Busbar dc systems can be designed to power a single building, or an entire city.

DC Busways: The Heart Of NextGen Power Infrastructure

In a world of progressively smart and linked, the demand for higher functionality as well as extra safe energies dispersal has actually become exceptionally critical. This is where enter busbar dc, the technology leading this change. One of the reasons behind busbar dc being so important lies in its ability to support more voltages and currents than traditional systems, allowing it to deliver more electrical power.

The compact design of busbar dc also makes it more reliable, since it has fewer components likely to fail. In other words, less systems will go down or experience a breakdown, an important step towards the evolution of power infrastructure as busbar dc helps to create more dynamic and optimized networks.

Busbar dc outperforms in power quality and availability besides efficiency, comfort of adaption. It does this even better than a standalone system, providing clean stable power by filtering out electrical noise and interference common to most traditional systems. It is especially valuable for sensitive equipment such as your servers and medical devices.

Busbar dc also has an automated fault detection system so that in case of a problem we can easily switch to backup systems, therefore preventing power outages which would normally disrupt our daily lives.

Busbar dc technology is uniquely cost saving The system is more efficient, flexible and reliable than conventional systems with less resources consumed for operation and maintenance.

This, in turn, makes busbar dc a new class of technology solutions that not only simplifies the integration of renewable energy sources such as solar and wind power into our electrical grid but also enables cost savings. That makes it much better at dealing with the varying power outputs of these sources compare to a traditional systems.

The world of electrical power is experiencing an extraordinary progress as far as busbar dc technology has been introduced with which the ordinary constructions also are trendy among persons these days. Busbar dc offers several advantages over traditional systems, such as increased efficiency, flexibility, reliability and cost savings in terms of power quality that could well position it to be a central enabler for the future connected and technology enabled world.

Kinto, a leading manufacturer busbar, was founded in 2005. It covers an area of over 8000 square meters. The company is dedicated to the creation of innovative energy storage and transmission products along electronic appliances and communication. They have years expertise and industry-leading technology. The company has introduced advanced processing equipment's, as well a wide range of precise testing tools to ensure that each product meets high standards of quality busbar dc. The R and D team and technical staff have extensive knowledge and expertise in delivering custom solutions a range of demanding processing requirements.

Kinto is constantly focusing on customers and offering superior customer service that will result in the goal of a win-win for everyone. Our professional customer service team is on hand to gather and analyze feedback from customers suggestions. This allows us to improve the busbar dc of services and products. We have established a long-term and good cooperative partnership many large and medium-sized enterprises home and abroad, such as Danfoss, Ballard, Methode Electronics, MARQUARDT, WEICHAl, RPS Switchgear, FLEXLINK, Mersen, ABB, SIEMENS, ChangyingXinzhi, OLIMPIA, VACON.

Kinto focuses on cost control improvement by constant optimization of manufacturing processes. Reduce the amount of waste generated by raw materials and equipment and increase the efficiency of equipment, in addition to other things, to ensure effective control. The long-term steady busbar dc with suppliers assures the viability of raw material procurement costs. Also, it is constantly introducing new technologies and equipment increase the efficiency of processing and quality of the products and reduce production costs. We able to offer our customers cheaper prices, while ensuring product quality. This is win in terms of cost control and competitiveness.

It is accredited by ISO 9001 ISO14001 as along with IATF 16949. The company controls every link the acquisition of raw materials to production process to finished product inspection to ensure stable reliable quality of its products. Additionally, it adopts a management system that is digital boost efficiency in production and improve accuracy. The management of busbar dc drawings digitally using EDM system offers accuracy and traceability, as well as strong support for product design and production.

Copyright © Kinto Electric Co., Ltd All Rights Reserved