Ever have one of those, how the heck does electricity get from this back room to that front facing wall type panic attacks? It’s quite interesting! One thing crucial for this is an electrical panel called the circuit breaker. It simply, a large box having different components such as circuit breakers, fuses and switches where used to control the electricity in your home. These components cooperate to transport electrical power throughout a building and ensures that every installation receives the sufficient energy it requires.

What is a busbar in an electrical panel What Are Busbars? - OK, so busbars are essentially the metal strips (or rods) that transfer electricity between the various sections of this panel. They are constructed of very good electrical conductors such as copper and aluminum. Meaning, they can be transported electricity very efficiently with little power lost in each transfer.

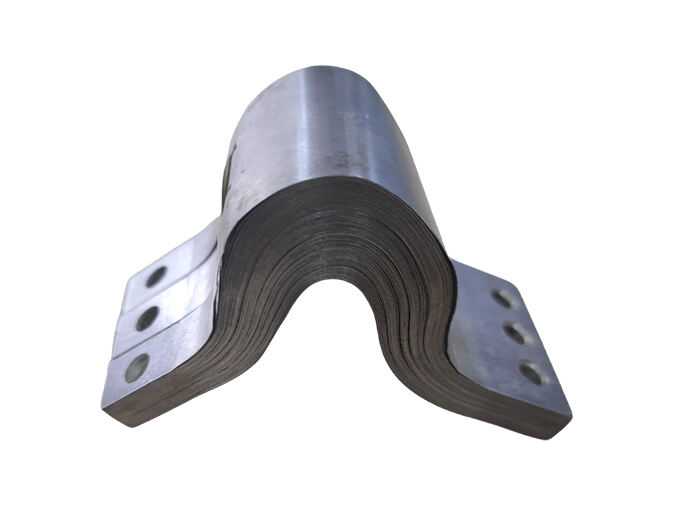

Followings are types of Busbars: Sandwich busbar Tubular tobus bar Flat type bus bar Each type is tailored to work best with different types of electrical panels. That is to say, one type of busbar may perform better than the other based on how you construct your panel.

Size of Busbar: Size is the most important aspect of a busbar and it depends on how much electrical capacity has to be carried through these bars. Otherwise, if a busbar need to carry high amount of electricity then it will have more thickness. This means that it will be able to bear the stress without either breaking down or overheating.

Busbar Insulation:- These are the material used to cover busbars in order not come under touch and unsafe from a number of people getting electric shocks. This is called insulation. Other insulating materials, such as PVC help to prevent accidents by ensuring the electricity can move only where it is supposed to go and not through places that might result in harm.

Efficient energy transfer: Busbars are manufactured from materials that conduct electricity with little to no resistivity (aluminum or copper). This result in less energy wasted when the electricity is sent passing through them It helps improve energy efficiency by finding a wide range of potential problems Computer cases are built with grooves which provide an easy air channel to cool the parts and have openings (front, back etc).

Easier to Maintain - Busbars can be very big and designed for high loads, meaning they fail less than wiring. They are that dependable you will not have to spend major money or time investing in maintenance, so for any electrical system they make an attractive choice as well.

Kinto is top manufacturer of busbars, was founded in the year 2005. It covers an area of more than 8000 square meters. Kinto is committed to the development of new energy storage and transmission technologies along electronic appliances and communication. Kinto has a wealth of experience and industry-leading technology. Kinto introduced cutting-edge processing equipment's and a selection high-quality testing equipment to ensure that every product meets the highest busbar in electrical panel requirements. The R and D team and technical team have deep knowledge and experience in delivering custom solutions a range of processing needs that are complex.

It is certified through ISO 9001 and ISO14001 as along with IATF 16949. The company strictly control every link raw material procurement through production to final product inspection to ensure stable reliable quality of the product. In addition, it implements a digital busbar in electrical panel system boost efficiency production and precision. The management technical drawings digitally with the EDM system ensures highest level of traceability and accuracy in addition to providing solid support for product development and manufacturing.

Kinto always places customer first and provides exceptional customer service to create a win-win situation. Our customer service busbar in electrical panel highly skilled and is on hand to gather and analyze customer feedback suggestions. This allows us to enhance our products and services. We have established a long-term and good cooperative partnership with many large medium-sized enterprises at home abroad, such as Danfoss, Ballard, Methode Electronics, MARQUARDT, WEICHAl, RPS Switchgear, FLEXLINK, Mersen, ABB, SIEMENS, ChangyingXinzhi, OLIMPIA, VACON.

Kinto focuses on cost control improvement by constant optimization of manufacturing processes. Reduce the amount of waste generated by raw materials and equipment and increase the efficiency of equipment, in addition to other things, to ensure effective control. The long-term steady busbar in electrical panel with suppliers assures the viability of raw material procurement costs. Also, it is constantly introducing new technologies and equipment increase the efficiency of processing and quality of the products and reduce production costs. We able to offer our customers cheaper prices, while ensuring product quality. This is win in terms of cost control and competitiveness.

Copyright © Kinto Electric Co., Ltd All Rights Reserved