A busbar is a very large component in the station. A busbar is just a large chunk metal rod through which the electricity travels from one end of substation to another. It is like a motorway for electricity. It connects various regions of the substation, enabling electricity to flow efficiently from one part to another. It is a very important connection because it ensures that the electricity can be conveyed without any latency.

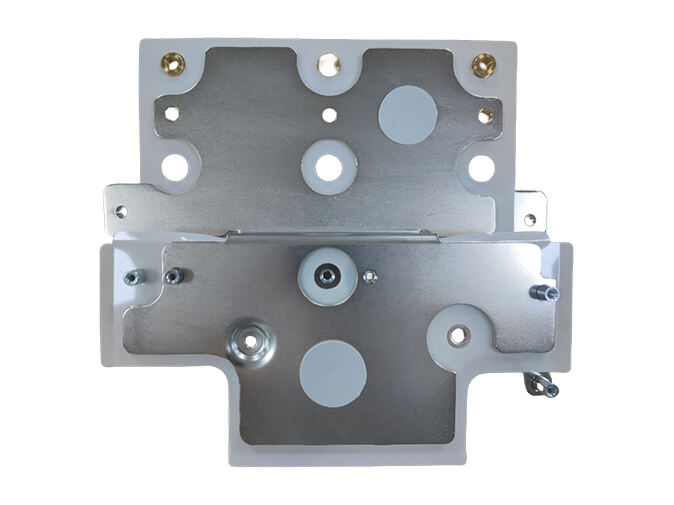

Different shapes and sizes of busbars, according to the substation requirements [Credit: High Report] Busbars are either flat and wide, round or rectangular shaped. Every design has its own characteristic. They are typically copper or aluminum, as these materials transmit electricity very well. It is often made from copper because it conducts electricity so well, or aluminum because lightweight and cheap.

Busbars are key components in the design of a substation therefore their building in this type to substations requires careful engineering and planning. Strong: The busbars have to be strong enough so that it can hold all the wire and other equipment attached with them. This means the engineers need to consider how much electricity will flow through the busbars and as a result, getting it all secure. They must also be certain that the busbars are sturdy enough to carry all of this electricity without heating up too much or causing issues such as short-circuiting, which will result in outages.

Busbars prevent power failure and connect different parts of the substation. They literally balance the flow of electricity to where it is needed! They help to regulate the traffic of electricity keeping it available for other users also. So even when we cook, power up our computers or watch television - busbars play a key role in ensuring that there is electricity enough for all.

The use of a high-quality busbars at a substation can reduce the risk that other accidents or safety challenges will occur. There are helping in working of substation to prevent the energy loss and also reducess it. This means greater efficiency as more of the electricity generated eventually gets to where it needs to go--our homes and buildings. Not only is increased efficiency good for the power grid, it also helps preserve money and resources over time.

After all, as technology improves new ideas spring up on power management strategies. Busbars are a part of this and really there's is a lot going on in the world bus work. Electrical Engineering is one of the biggest engineering and science topics that engineers, scientists research always hoping for good ways to make electricity distribution better or even perfect.

Some busbars, for example have now been manufactured with new materials or coatings that work better and last longer. These benefits can render the busbars resilient to wear and tear as would be necessary in substations that handle large capacities. Some other busbars with sensors and monitoring so that workers can see how they are performing live. That way if any problem does crop up, it can be identified and addressed in short order keeping the juice flowing nicely.

Kinto always puts customer first and offers excellent customer service in order to achieve win-win growth. Our customer service department highly skilled and is on hand to collect and analyze feedback from customers suggestions. This allows us to improve our products and busbar in substation. We have established a long-term good cooperative partnership with many large medium-sized enterprises at home and abroad, such as Danfoss, Ballard, Methode Electronics, MARQUARDT, WEICHAl, RPS Switchgear, FLEXLINK, Mersen, ABB, SIEMENS, ChangyingXinzhi, OLIMPIA, VACON.

It is accredited by ISO 9001 and ISO14001 as and IATF 16949. To ensure consistent and secure quality, the firm controls every aspect the process starting from procurement of raw materials all the way production until product busbar in substation. It also adopts digital management system to improve production efficiency and accuracy. The management technical drawings digitally via the EDM system offers transparency precision, as well as strong support for product design and production.

Kinto, a leading manufacturer busbars, was created in the year 2005. It covers an area of over 8000 square metres. The company is dedicated to the development of revolutionary energy storage and transmission technologies along electronic appliances and communication. Kinto is a renowned company with wealth of experience and industry-leading technology. The company has introduced advanced processing equipment's a selection of precise testing tools to ensure that every product is in line with the highest standards quality standards. R and D and technical personnel have years of experience and expertise in providing customized solutions to address a wide range of complex busbar in substation needs.

Kinto focuses on cost control improvement by constant optimization of manufacturing processes. Reduce the amount of waste generated by raw materials and equipment and increase the efficiency of equipment, in addition to other things, to ensure effective control. The long-term steady busbar in substation with suppliers assures the viability of raw material procurement costs. Also, it is constantly introducing new technologies and equipment increase the efficiency of processing and quality of the products and reduce production costs. We able to offer our customers cheaper prices, while ensuring product quality. This is win in terms of cost control and competitiveness.

Copyright © Kinto Electric Co., Ltd All Rights Reserved