The use of cooper busbars is extremely important in establishing a good electrical system, because it can share powers well. These are busbars made of copper, which is very good at conducting electricity. In any factory, lighting busbars come in handy when it comes to a peaceful and safe operation of things.

Cooper busbars are important in electrical system, as they allow electricity to flow from power source to various parts.’ They can distribute power more evenly so that all devices get the same amount of electricity and all work well. For a busy electrical system to function efficiently, it would be difficult to control the flow of electricity without cooper busbars.

A major advantage of using copper busbars is that copper is a great conductor of electricity. In other words, it can conduct a lot of electrical current without overheating. Here is where it gets less intuitive, particularly in terms of factories, where much electricity is required to power machines.

Second, 300 amp busbars also are strength, thus being more resilient and durable. Copper is tough stuff, a big reason it’s a great material for electrical systems that are expected to function 24/7. Cooper busbars can tolerate heat and stress, and they function very well over time.

Cooper busbars make factories work better by ensuring a secure and consistent connection for distributing power. They can be easily installed and combined with other electrical components, so that capacity can be cut down as well as maintenance costs. Factories can ensure electricity sharing efficiency, have more work done and less energy used by employing the cooper busbars.

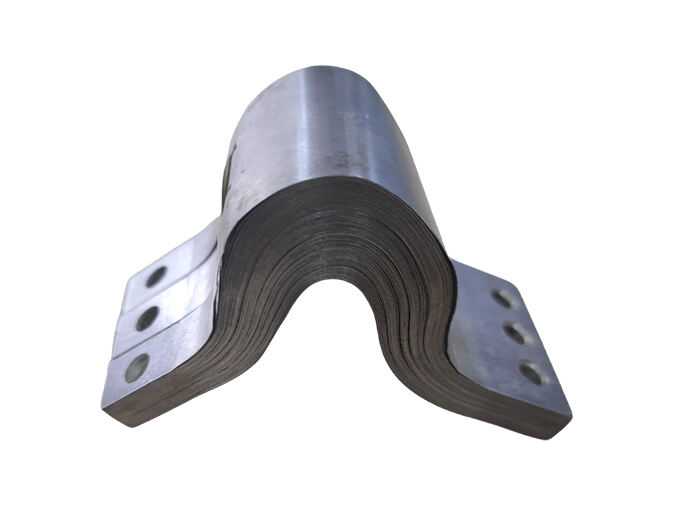

Cooper bus bars can be customized to the shape and size that is required for each electrical application. They’re available many shapes and sizes to aid installation in small, odd spaces. Cooper busbars can also be modified or expanded to accommodate new electrical requirements, providing a flexible option to distrbute powere.

One of the important aspects of an electrical system is safety and a good quality cooper busbar helps to keep safety in your facility. Cooper busbars are engineered to provide safe and dependable performance and protection from the hazardous effects of electricity. Selecting copper busbar of high-quality can reduce the risk of electrical problems, fires, and other safety issues in your facility.

Kinto always places customer first and provides exceptional customer service to create a win-win situation. Our customer service cooper busbar highly skilled and is on hand to gather and analyze customer feedback suggestions. This allows us to enhance our products and services. We have established a long-term and good cooperative partnership with many large medium-sized enterprises at home abroad, such as Danfoss, Ballard, Methode Electronics, MARQUARDT, WEICHAl, RPS Switchgear, FLEXLINK, Mersen, ABB, SIEMENS, ChangyingXinzhi, OLIMPIA, VACON.

The company always puts quality of the product the first place, it's accredited through ISO 9001, ISO14001, IATF 16949, and various other certifications. To ensure consistent and reliable quality, the company controls every step procurement of raw materials to production until product inspection. It also adopts a digital management system to improve the efficiency of production and improve cooper busbar. The digital management technical drawings with the EDM system ensures the accuracy and reliability of drawings. It also provides solid support for the development of products and production.

Kinto is focused cost management and continuous improvement of production processes. Reduce waste in raw materials and equipment and optimize the use of equipment, in addition to other strategies, in order to achieve effective control. The quality of the raw materials costs is assured a long-term and stable relationship supplier. In addition, it continually introduces new technologies and equipment in order to enhance production efficiency quality, thereby further reducing production costs. These measures cooper busbar us offer customers more affordable prices, while also ensuring product high-quality, and to achieve ideal balance between cost control and market competitiveness.

Kinto is renowned manufacturer busbars, was established in 2005. It covers an area of 8000 square meters. The company is dedicated to the creation innovative energy storage and transmission products addition to electronic appliances and communication. They have years of knowledge and expertise, as well as industry-leading technology. Kinto has developed advanced processing equipment's a variety of testing tools that are precise to ensure that every product meets highest standards of quality cooper busbar. The R and D team and technical team have deep knowledge and experience in delivering custom solutions to a range of complex processing requirements.

Copyright © Kinto Electric Co., Ltd All Rights Reserved