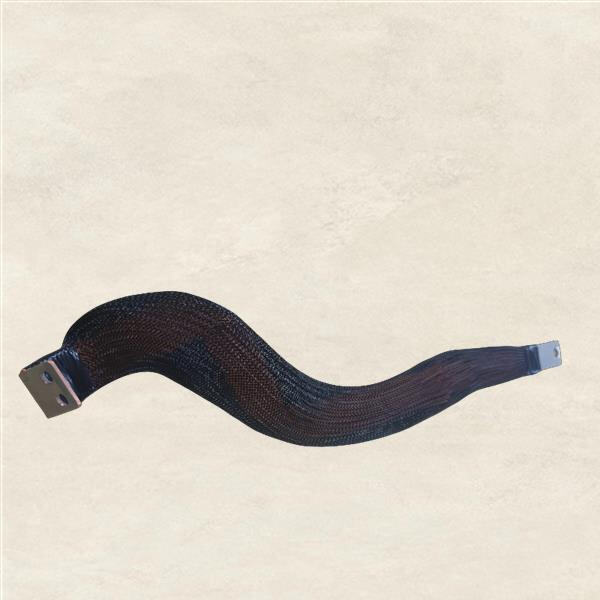

The critical role of such flexible busbars in energy management solutions around several systems has been highlighted. These are those little or thick proprietary bendable wires that keep an electrical connection secure in a small space and they get made of copper usually. Copper is a more flexible conductor and therefore, it efficiently transports electricity. That is insulated for its safety so that the busbars can not cause any accident. It acts as if it catches lightning in a bottle, sends the electricity through where you want it and keeps things running smoothly on its way to far end of a system.

ICAN: The application of flexible busbars prompts a reimagining for resource energy-management.(CAINEN DIWUN) The old school style of busbars made the construction heavy and stiff, large in size which also means a non-easy reconfigurable way. The old busbars are stiff and rigid, thus making them unacceptable for use in most applications. All in all, though the flexible busbars are real winner for me! So the more lightweight it is to expand them, and because of this they are faster to come alive. They can be usually placed anywhere we want them to go within a system meaning that it provides us with more flexibility when organizing and configuring an electric setup.

Flexibles busbarsOne advantage of flexible bus bars is that they can work well in systems which are subject to frequent changes. In the vast majority of use cases, some parts in a system will have to be moved or replaced more often than others. This will necessitate a redesign to scale, and disposal or replacement of many large busbars. This Billet could easily get settled in these new once without throw out such flexible turns-in type of busbar at that time. In that regard, they are also good for mutable environments. With this, instead of spending on new components every time a change in spec is made or necessary we can simply adjust the pre-provided flexible busbars to comply with that.

In essence, flexible busbars are set to be the future of power delivery in electrical systems. They have a number of advantages over the old bulky busbars. Less resistance waiting for you is one of the primary benefits but also performance gains as well. The point is, they are capable of doing so which in turn makes them consume even less process energy and that means it does save some power after all. Moreover, these bendy busbars are less difficult to install and accommodate lesser space. This design is most appropriate for tight confines, where traditional busbars cannot matching a fit.

When establishing an electrical system, the presence of flexible busbars really is a plus point. These are a type of energy-conserving, and can increase system performance. They should last longer as they are designed for movement, so will be less fragile over time. This, in turn makes their contenders stronger or more reliable — than most / all previous which are much many fewer that it does not torque on. In the end it help you having an efficient & reliable system with flexible busbars.

Kinto always puts customer first and offers exceptional customer service to flexible busbar growth both parties. Our professional customer service team is always available to collect and analyze feedback customers and ideas. This helps us enhance the quality of our services and products. We have established a long-term good cooperative partnership with many large and medium-sized enterprises home and abroad, such as Danfoss, Ballard, Methode Electronics, MARQUARDT, WEICHAl, RPS Switchgear, FLEXLINK, Mersen, ABB, SIEMENS, ChangyingXinzhi, OLIMPIA, VACON.

Kinto is a renowned manufacturer of busbars, was created in the year 2005. It covers a space of around over 8000 square metres. The company is dedicated to the development of new energy storage and transmission equipment along with electronic appliances and communication. They have years of knowledge and experience, as well as the most advanced technology. The company has invested in modern processing equipment's and various testing tools that are precise in order to ensure that each product meets the highest standard of quality. R and D and technical experts have deep expertise and practical experience for providing custom flexible busbar to meet a wide array of demanding processing requirements.

It is certified through ISO 9001 and ISO14001 in addition to IATF 16949. To ensure constant and reliable quality, the firm controls every aspect of the process from raw material procurement through production until product inspection. It also employs computerized management system that improves production efficiency and accuracy. The digital administration of technical drawings using the EDM system guarantees the accuracy and reliability of drawings. Provides an unbeatable support to product development and flexible busbar.

Kinto focuses on cost control improvement by constant optimization of manufacturing processes. Reduce the amount of waste generated by raw materials and equipment and increase the efficiency of equipment, in addition to other things, to ensure effective control. The long-term steady flexible busbar with suppliers assures the viability of raw material procurement costs. Also, it is constantly introducing new technologies and equipment increase the efficiency of processing and quality of the products and reduce production costs. We able to offer our customers cheaper prices, while ensuring product quality. This is win in terms of cost control and competitiveness.

Copyright © Kinto Electric Co., Ltd All Rights Reserved