Laminated copper busbars are rare parts in electricity that many of all different industries are beginning to use. These bus bars provide various advantages over the distribution of power in conventional electrical systems.

A major advantage of laminated copper busbars is their high electrical conductivity. That means they can transport electricity from one spot to another without losing much of that energy. That’s to help ensure the power being shared is power doing something.

Another advantage is that laminated copper bus are very strong. They can withstand the test of time; they won’t break or degrade that easily. And this is especially critical in electrical systems, because the parts need to be reliable and long-lived.

Laminated copper bus bars are inherently strong and efficient. They work to near perfection due to the fact that they are copper, and have great electrical conductivity. What that means is, is that even though they move a lot of power they don’t get hot and they don’t lose a lot of energy.

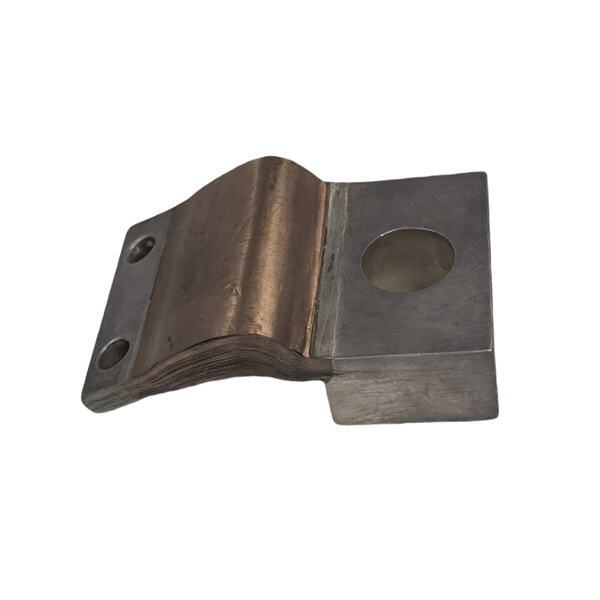

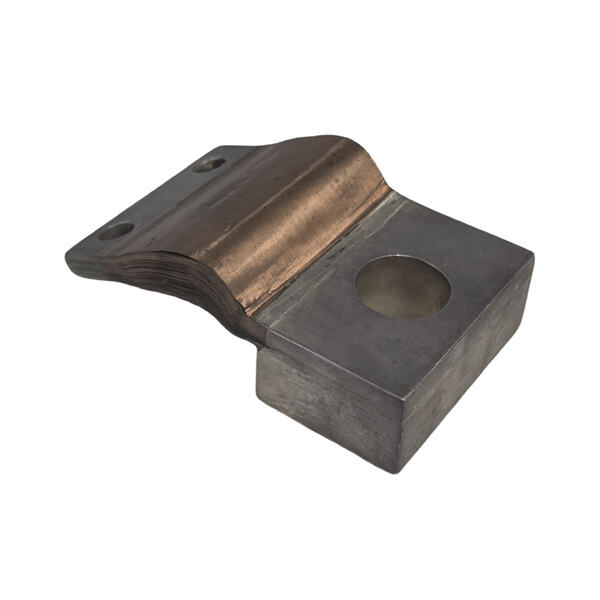

The reason for their strength is that they are built up from many layers of copper that are glued together. That makes for a very tough pellet that can withstand demanding conditions and scorching temperatures.

The structure of laminated copper busbars is critical. They comprise numerous layers of copper that are bonded together in a unique way. This makes them very tall and capable of carrying a lot of electricity.

The manner in which these busbars are manufactured is deliberate to make them function effectively in several scenarios. Unfortunately when you come to a lengthy overhang you are going to have a lovely flat piece roof with parapets with a flat wall.

Copyright © Kinto Electric Co., Ltd All Rights Reserved