Did you ever wonder how electricity travels from a power plant to your house or school? It travels through those long power lines and is passed through special devices known as transformers. These transformers are used to convert the electricity into a form that can be safely used in buildings. However, there is another tool for this called motor busbar. It is a special type of wear to take electricity from one point in the building or machine and distribute it properly inside. Read more about how this works!

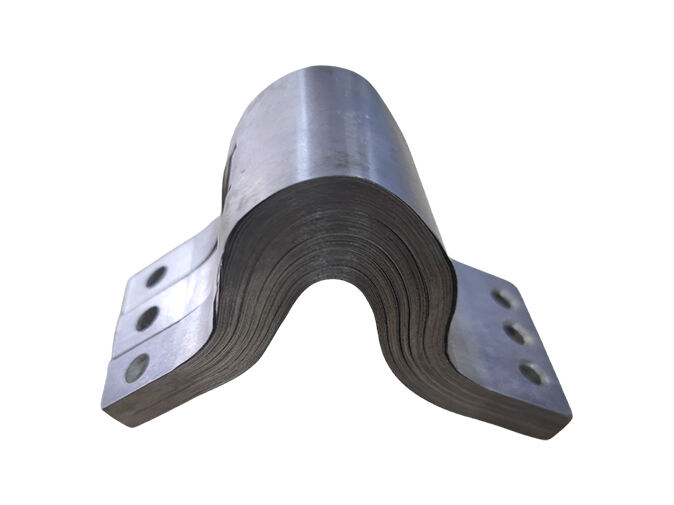

With the advent of motor busbar technology there are many uses for which it can be leveraged, and this article will detail one such exciting opportunity. Now the way we give power, and take it has also evolved with this technology rather than old cable system. The motor busbar is flexible, so it bends easily and will conform to the shape of any space. At the same time, it is very easy to install without any extra overhead of setting up logs. It is very helpful in complex electrical systems requiring many connection points.

Busbars in motor buses One of the most cost-effective advantages is probably that which can save a lot from using busbars over traditional wiring systems. The motor bus-bar can replace the harness for older wiring that thus requires fewer numbers of wires and cables to transport electric current. From a materials and installation point of view, this can greatly reduce the amount cabling needed that in turn means cost savings. Furthermore, as the motor busbar is intended to better manage electric power usage it helps maintain cleanliness by reducing hung wiring. This will also make a cleaner and safer environment for all.

A motor busbar system can help to enhance the rate at which electricity is used. In many cases, this system is the perfect solution for typical old wiring. This ranges from traditional lines that may sometimes lose power or become dangerously hot. A motor busbar is built to manage a massive electrical load, this in turn enables the smooth transfer of electricity without fine breaks. This implies that you can depend upon your electric framework to work effectively and not worry with things like overheating.

Another major benefit of a motor busbar solution is that it streamlines how electrical equipment connections are established. A typical example is a motor busbar which can save the requirement of wires and connections by using old wiring. Fewer paths of destructionProbably the most important reason for keeping a monolith deployment is few number connections. It gives the electrical system a life so that there is no way to break down in addition, it helps you out for maintaince.

Kinto is a leading busbar manufacturer founded in 2005 and covers an area of 8000 square metres and is committed to development of new energy storage, transmission and distribution products, electronic appliances and communications using the most advanced technology the market and extensive production experience. Kinto has invested in cutting-edge processing equipment's as well an array of high-quality testing instruments which ensure that every product is of the highest standard of quality. The R and D team the technical team have extensive knowledge and expertise in delivering tailored solutions a variety of motor busbar processing requirements.

Kinto always focusing on the client providing outstanding customer service to ensure an outcome that is win-win. A professional customer service team always available to collect and analyze feedback from customers and suggestions. This helps enhance our products and services. We have established a long-term good cooperative motor busbar with many large and medium-sized enterprises at home and abroad, such as Danfoss, Ballard, Methode Electronics, MARQUARDT, WEICHAl, RPS Switchgear, FLEXLINK, Mersen, ABB, SIEMENS, ChangyingXinzhi, OLIMPIA, VACON.

Kinto focuses on cost control and improvement constant optimization of production processes. Reduce the amount of waste generated by raw materials and equipment, and improve the utilization of equipment, in addition to other measures, to achieve effective control. The competitiveness raw materials guaranteed through long-term, consistent cooperation suppliers. The company also continuously introduces innovative production methods and equipment to enhance efficiency and quality of motor busbar of products, and thereby reduce costs of production. Our customers can enjoy better prices, whilst ensuring the highest quality. This is a win-win situation for cost control competitiveness.

It is accredited by ISO 9001 ISO14001 as along with IATF 16949. The company controls every link the acquisition of raw materials to production process to finished product inspection to ensure stable reliable quality of its products. Additionally, it adopts a management system that is digital boost efficiency in production and improve accuracy. The management of motor busbar drawings digitally using EDM system offers accuracy and traceability, as well as strong support for product design and production.

Copyright © Kinto Electric Co., Ltd All Rights Reserved