We visualize wires and circuits carrying electricity to our homes, gadgets etc. whenever we talk about power. But would you believe there is a bus bar out in the world? A bus bar is a metal that helps to transmit electricity from one source place. kinto nickel busbar is very important in electrical systems. The metal is made by most of the bus bars for copper as it can transmit electricity with great conductance. This allows it to pass an electrical current with minimal loss of energy. Nevertheless, copper can be damaged or deteriorate over time because of the various reasons behind this. Nickel plating comes to the rescue here

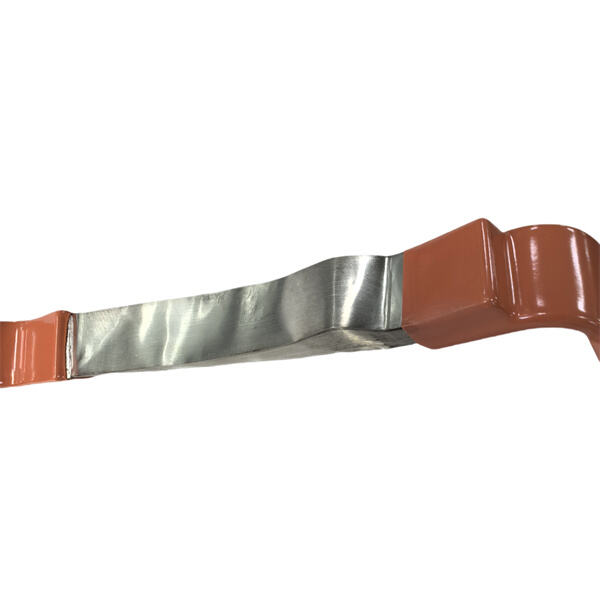

Nickel plating is a process that has to be done in order to coat the copper bus bar with nickel. This coating forms a robust and long-lasting surface that promotes the bus bar protection from getting injured. The busbar will last longer and perform more effectively as the result of this protective coating. Nickel Plated Copper Bus Bars can Exceed 4X Lifetime If the bus bars were to be coated with nickel, perhaps they would last up even longer. This nickel layer effectively serves as a shield between the copper and its surroundings (hair, water chemicals) which will otherwise corrode or fret it away over time.

They are used, for example with high-performance bus bars where very large currents must be supplied. This means private locations such as power plants, factories and even electric vehicles. The corporate says that these busbars are an vital hyperlink in the 3-phase half of their techniques and should be very sturdy to deal with all that electrical energy. One of the big reasons for using nickel plating is because it helps prevent bus bar from wearing down or getting damaged often. That dependability is important, particularly when you are working in a high-volume situation where any sort of failure could spell serious trouble.

This can also happen with time and particularly in harsh environments such as those that have a lot of salty air or other corrosive materials, like we discussed before. Copper bus bars are made stronger through the process of nickel plating, as it creates a protective barrier that can prevent any harm from happening to them. This kinto silver plated copper bus bar in turn allows for the bus bar to have an extended life and require less maintenance than this missing nickel plated layer would perhaps prompt you into undertaking. Fewer repairs make wind extremely low-maintenance thus saving businesses and industries both money and time.

Nickel plated copper bus bars are the best selection for any electrical work because they do provide a proven history of durability strength and price efficiency. They have the ability to conduct large amount of electricity without getting ruined, which makes them ideal for power generation plants and industrial machines. They are also maintenance free, especially compared to non-nickel plated bus bars which they exponentially more cost effective over the lifetime of use. That makes this a good investment for those who will be using bus bars in electrical applications.

Speed is a good thing when it comes to electrical work. A kinto tin plated copper bus bar can improve electrical performance by decreasing the energy loss. This layer of nickel on the bus bar creates a more planar surface that results in easier flow of electricity. Which means that for a huge job where efficiency is everything, less energy will be lost as heat in transmission. This can help companies to manage their energy more efficiently through nickel plated bus bars.

Kinto is focused on cost control improvement by constant optimization of production processes. Reduce the waste of raw materials and equipment and increase the efficiency of equipment, among other things, to ensure effective control. Long-term stable cooperative relations with suppliers ensures the competitiveness in the procurement of raw materials. In addition, it also continually introduces new technologies equipment in order to enhance the efficiency of production and product quality and reduce production costs. These measures enable us to give customers affordable prices maintaining product quality and achieve an ideal balance Nickel plated copper bus bar cost control and market competition.

It is certified by ISO 9001 ISO14001 as and IATF 16949. The company is able control each connection from the procurement of raw materials through production to final product inspection to ensure stable reliable quality of product. Furthermore, the Nickel plated copper bus bar implements a management system is digital to boost efficiency in production and ensure accuracy. The management of technical drawings digitally via EDM system offers transparency and precision in addition to providing solid support for development and manufacturing.

Kinto is a leading busbar manufacturer founded in 2005 and covers an area of 8000 square metres and is committed to development of new energy storage, transmission and distribution products, electronic appliances and communications using the most advanced technology the market and extensive production experience. Kinto has invested in cutting-edge processing equipment's as well an array of high-quality testing instruments which ensure that every product is of the highest standard of quality. The R and D team the technical team have extensive knowledge and expertise in delivering tailored solutions a variety of Nickel plated copper bus bar processing requirements.

Kinto always puts customer first and offers exceptional customer service to Nickel plated copper bus bar growth both parties. Our professional customer service team is always available to collect and analyze feedback customers and ideas. This helps us enhance the quality of our services and products. We have established a long-term good cooperative partnership with many large and medium-sized enterprises home and abroad, such as Danfoss, Ballard, Methode Electronics, MARQUARDT, WEICHAl, RPS Switchgear, FLEXLINK, Mersen, ABB, SIEMENS, ChangyingXinzhi, OLIMPIA, VACON.

Copyright © Kinto Electric Co., Ltd All Rights Reserved