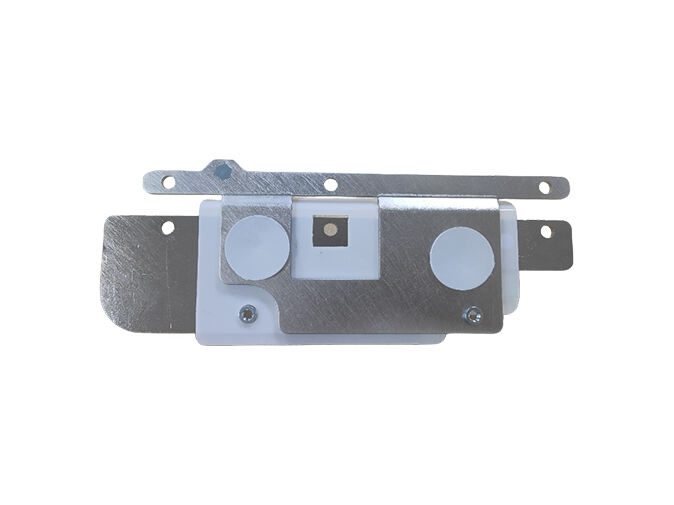

It is a distinct part of electrical machinery, Pin Busbar works in two ways it carries current from one location to another and creates voltage on the vias. It is filled with many pins which connect to various parts of the system and allows power to flow throughout it as per normal. The pins are arranged in a shape to prevent electricity from traveling, thus sparks can also be minimized (physical sounds)

When you are looking at installing a Pin Busbar there will always be more decisions to make, and factors needing your attention. First you can get the pins to lay themselves out in a manner that should enable optimal performance. If you have to be a bit more cautious with planning and measure out parts, will go few not too difficult. Proper alignment is essential to ensure good electric power flow.

Pin Busbars have many benefits that culminate in their suitability to be used within electrical systems. And obviously, one of the major things that we get out of them is long-distance power transmission in a safe and efficient way. This eventually becomes more significant as it saves you from making many complex connections that hamper performance when scaling large (in buildings or facilities)

Stronger and last longer: This is another essential advantage of a Pin Busbar. Therefore, they could be depended to work outside in harsh climate conditions. They are also designed to work in dusty and dirty working conditions so they can function in the end. This will allow them to last longer, and performance over time in harsh environments is less likely degrade.

The Pin busbars would be designed based on each particular function within different configurations. For instance, a few Magnetic Grids are worked for low voltage applications and others have been intended to meet the specific needs of high volgtage application with magnet grids. As a result, they are able to meet with the diverse electrical needs across various applications.

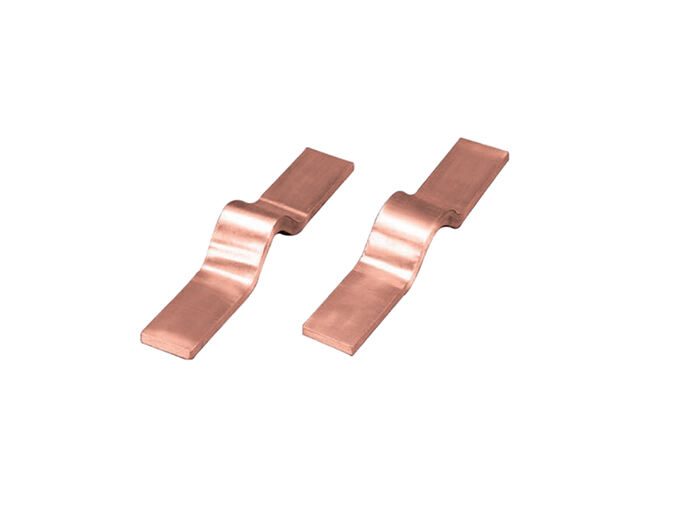

Lastly, the material from which Pin Busbars are produced can also vary. A bigger resistance wire that is produced through the cable television much better performs electrical energy, as copper has an extremely high rate of conductance -- so while more resistant wires will likely include copper cables others might be made from aluminum. Material, regardless of type must match whatever individual specifications are needed for the system to perform properly.

In order to keep your Pin Busbar working right, regular inspection and cleaning are essential. When you do this consistently, it will help ensure that pins are properly aligned and there aren't any connections loose or otherwise preventing optimal operation. This is essential to ensure the proper functioning of the processing, and for security reasons.

Kinto always is a customer-centric company offers exceptional customer service in order to achieve win-win growth. Our customer service department highly pin busbar and is always available to collect and analyze customer feedback ideas. This helps us improve our products and services. We established a long-term and good cooperative partnership with many large and medium-sized enterprises at home abroad, such as Danfoss, Ballard, Methode Electronics, MARQUARDT, WEICHAl, RPS Switchgear, FLEXLINK, Mersen, ABB, SIEMENS, ChangyingXinzhi, OLIMPIA, VACON.

Kinto is focused on cost management improvement through continual optimization of manufacturing processes. Reduce the amount of waste generated by equipment and raw materials and enhance the efficiency of equipment, among other strategies, in order to achieve effective control. Long-term and stable cooperative relations with suppliers assures viability of procurement costs for raw materials. In addition, it constantly introducing new production technologies and equipment that improves production efficiency quality and reduce production costs. This helps us offer our customers better affordable prices while maintaining product quality an optimal pin busbar of cost control and market competitiveness.

It is accredited through ISO 9001 and ISO14001 along with IATF 16949. To ensure consistency and reliability quality, the company oversees each step of the process, from procurement of raw materials to production, to inspection products. The company also implements a digital management system boost production efficiency and accuracy. The digital administration technical drawings using the EDM system ensures the accuracy and reliability drawings. It also provides solid pin busbar for product development and production.

Kinto is a top manufacturer busbars, was founded in 2005. It covers a space of around 8000 square meters. The company is dedicated to the development new energy storage and transmission equipment, as well electronic appliances and communications. They have years of knowledge and expertise, as well as industry-leading technology. Kinto has introduced cutting-edge processing equipment's and a selection of high-quality testing equipment ensure that every product meets high standards of quality requirements. R and D and technical staff have years experience and expertise in providing customized solutions for a broad pin busbar of processing requirements are complex.

Copyright © Kinto Electric Co., Ltd All Rights Reserved