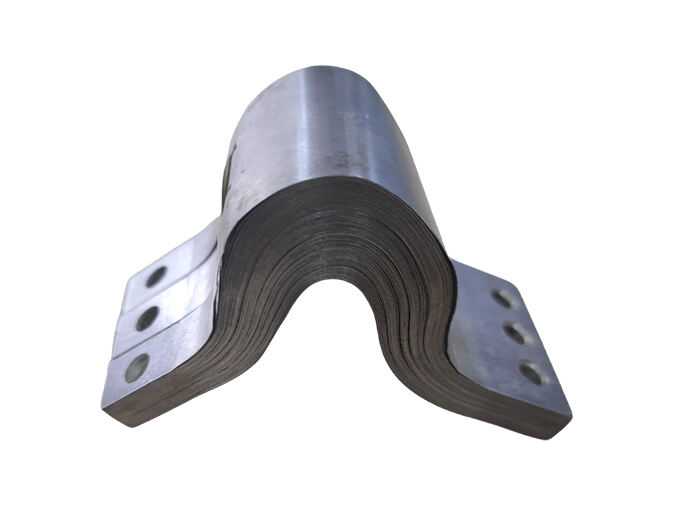

Tinned Busbar should be your way out when you have a massive power that needs to conveyed in an Expansive and safe manner. The Tinned Busbar - It is a copper wire that has been tined, or coated with a thin layer of tin. Its applications are widespread, e.g. power substations, switchgear installations or in the industrial factory halls for transformer rooms.

The use of tinned busbar has become so popular within the electrical engineering and design communities due to several inherent advantages. One of its main advantages is that it has a high electrical conductivity. Copper is really an amazing conductor of electricity and the tin coat doesn't change that, but it does so than more awesome in fact. The cross-sectional contact area at the interface between adjacent busbars is maximized, which allows a higher amount of power to be transferred; as such tinned bar can work particularly well in circumstances that require heavy currents to transport.

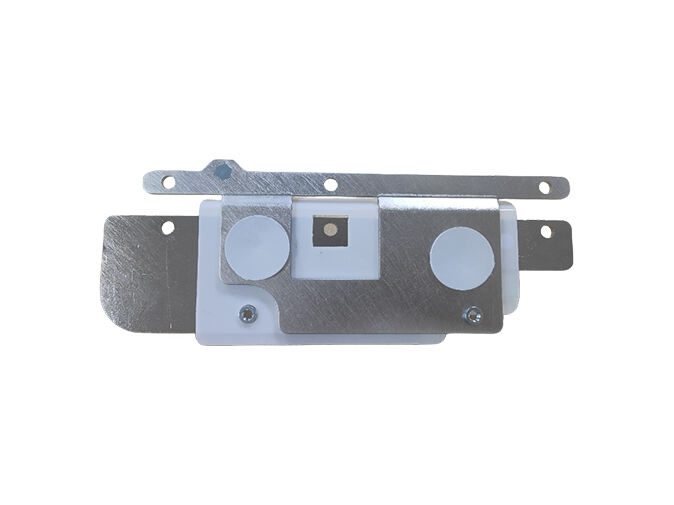

The manufacturing process of tinned busbar has a lot to do with its quality and trustworthiness for use in areas where electricity is used. First, the copper is formed to the desired shape before being cleaned and dried very carefully in order for it not have any impurities. The latter sheets are immersed in a hot tin bath, after which the copper is tinned. They improve the properties of copper conductor such as anti-corrosion and high temperature resistance by this tin coating. The tinned busbar is then accurately fabricated (cut, drilled) and assembled before packing.

Tin coating tin busbar is helpful to the realization of its long service life and high efficiency. The insulation provides a barrier against corrosion that would otherwise penetrate the copper core, prevent any chemical exchange surrounding or within wires and seep through to create buildup of corrosive deposits which can lead to breakage in conductors. Untinned copper, on the other hand is not as heat resistant and capable to sustain such temperatures without being damaged or losing performance.

Tinned busbar as a perfect choice for heavy current and high temperature applications Its great conductivity allows it to handle high power loads, and its outstanding heat resistance ensures that even in the hottest environments you can still operate without worry. For this type of power installations, the properties of tinned busbar are ideal to allow operating at these high levels.

Benefits of Tinned Busbar in Aggressive Atmospheres and Difficult Working Area

Mersen tinned busbar offers protection against corrosion, especially in harsh environment sites where traditional copper conductors could damage and impact desired performance or failure. The tin plating on the copper provides protection from damage that might result if the new busbar came into contact with moisture or chemicals. In such a diverse area of applicability, this makes it essential when specified on marine & offshore installations and chemical plants etc.

So, in the closing this article Tinned busbar is proven to be most suited for esteemed powered applications and its demands on reliability, durability and performance. It is one of the vital components in Electrical Power systems as it can withstand high current load and also work under stressed environment. Tinned busbar is an ideal solution for multiple requirements in power applications due to its high conductivity and longevity.

It is accredited through ISO 9001 and ISO14001 as in addition to IATF 16949. To ensure consistent secure quality, the firm controls every stage of production, from procurement of raw materials production until product inspection. In addition, it implements a digital management system boost production efficiency and ensure accuracy. Digital management of technical drawings using the EDM system gives precision traceability along with strong support for product tinned busbar manufacturing.

Kinto is a renowned manufacturer of busbars, was founded the year 2005. It has a total area of over 8000 square metres. The company is dedicated to the development of revolutionary energy storage transmission products in addition to electronic appliances and communication. They have a wealth experience and industry-leading technology. Kinto has invested in the latest processing equipment's various testing tools that are precise in order to ensure each product is of the highest standards of quality. The R and D team and technical staff have tinned busbar expertise experience in providing customized solutions for a variety of processing needs that complex.

Kinto focus on cost control efficiency enhancement, through continuous optimization of manufacturing processes, reducing wasted raw materials, and improve utilization of equipment, among other ways effective cost control. The competitiveness of the raw material costs is ensured by a long-term and stable relationship supplier. In addition, it also continually introduces new technologies and equipment order to enhance processing tinned busbar and product quality and reduce production costs. These steps allow us to offer our customers better competitive prices while ensuring product quality and ideal balance between cost control and market competition.

Kinto always puts its focus on the customer provide superior customer service that will result in win-win development. A knowledgeable customer service team available to collect and analyze feedback from customers and ideas. This helps improve the quality of our services and products. We have tinned busbar a long-term and good cooperative partnership many large and medium-sized enterprises at home abroad, such as Danfoss, Ballard, Methode Electronics, MARQUARDT, WEICHAl, RPS Switchgear, FLEXLINK, Mersen, ABB, SIEMENS, ChangyingXinzhi, OLIMPIA, VACON.

Copyright © Kinto Electric Co., Ltd All Rights Reserved