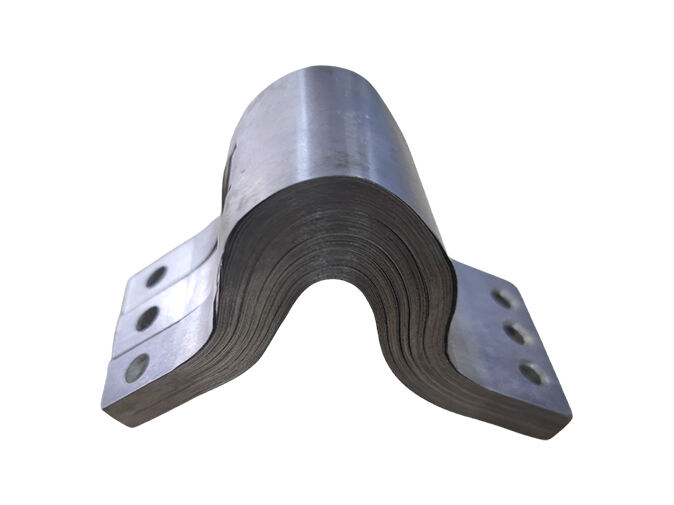

Tinned copper busbar is a type of material that is used in electrical works. The kinto tin plated copper bus bar is copper, which is an excellent conductor of electricity. The copper is coated with tin, which allows it not to rust and to work even better. That is why tinned busbar copper is a better option for the bulk power systems.

Another advantage of using tinned copper busbar is that it endures longer life. The tin coating prevents the copper from rusting, which can occur when the copper becomes wet or is exposed to the elements. What this enhances to is tinned copper busbar’s capability to remain strong through many years without changing, which is a fantastic alternative for industries.

It has the further advantage of being a very good electrical conductor. Copper already does pretty well at this, but the tin coating makes it work better. This is why tinned copper busbar is used to conduct electricity around a building so effectively, ensuring electrical systems are well maintained and safe to use.

It also has a tin layer on the outside, which inhibits rusting. Rust can eat away at copper, ruining electrical elements and being physically dangerous. Because of that tin coating, that kinto tinned copper busbar is protected from rust, which means that tinned copper busbar is sturdy and reliable even in the most difficult circumstances.

In addition to the strength and electrical conductivity of our tinned copper busbar, it is also a high efficiency and low-cost solution to use for industrial power systems. It’s long lasting, so it can save companies money on repairs and replacements down the line. That makes kinto tin plated copper bus bar a sound good investment for companies that want to make their electrical systems work better and be more predictable.

When selecting tinned copper bus bar for electrical systems, one must consider what the system requires. Tinned copper busbar is available in many shapes and sizes and it is important to select the appropriate piece for your specific application. A good supplier like Kinto is able to explain your options and assist with designing, fabricating and ordering the best kinto tin plated aluminum bus bar for what you need.

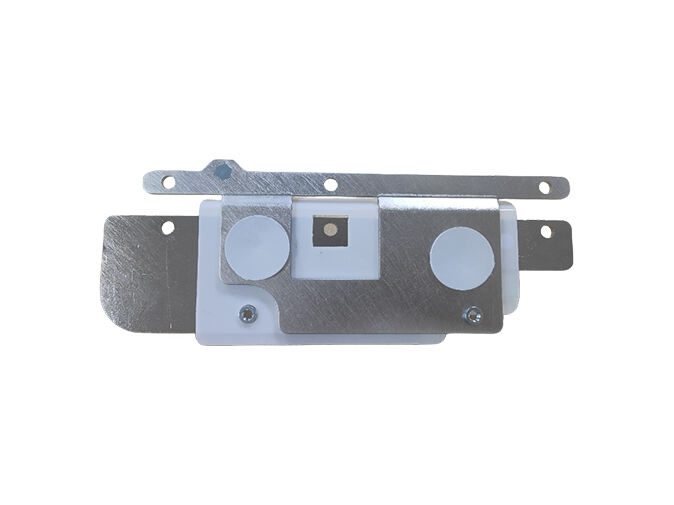

Kinto, a leading manufacturer busbar, was founded in 2005. It covers an area of over 8000 square meters. The company is dedicated to the creation of innovative energy storage and transmission products along electronic appliances and communication. They have years expertise and industry-leading technology. The company has introduced advanced processing equipment's, as well a wide range of precise testing tools to ensure that each product meets high standards of quality Tinned copper busbar. The R and D team and technical staff have extensive knowledge and expertise in delivering custom solutions a range of demanding processing requirements.

Kinto is focused on cost control continuous improvement of manufacturing processes. Reduce the amount of waste generated raw materials and equipment, and enhance the efficiency of equipment, in addition to other things, to ensure efficient control. A long-term, stable and reliable relationship with suppliers will ensure the efficiency in procurement of raw materials. We also constantly introduce Tinned copper busbar production methods equipment to enhance the efficiency and quality of processing of the products decrease production costs. Our customers can enjoy better prices, while maintaining product quality. This is a win in terms cost control and competitiveness.

Kinto always places the customer first offers exceptional customer service in order to create a win-win situation. Kinto has a Tinned copper busbar customer service department will constantly collect customer opinions well as suggestions to improve the quality of services products. We have established a long-term and good cooperative partnership with many large medium-sized enterprises at home and abroad, such as Danfoss, Ballard, Methode Electronics, MARQUARDT, WEICHAl, RPS Switchgear, FLEXLINK, Mersen, ABB, SIEMENS, ChangyingXinzhi, OLIMPIA, VACON.

It certified by ISO 9001 and ISO14001 as and IATF 16949. To ensure consistent reliable quality, the company controls every step raw material procurement through production and inspection of product. Additionally, it Tinned copper busbar a digital management system to boost efficiency in production and accuracy. Digital management of technical drawings through the EDM system ensures accuracy traceability in addition to providing solid support for product development manufacturing.

Copyright © Kinto Electric Co., Ltd All Rights Reserved