This is where the efficiency comes as one of the main factors and also another important role ) For over a century, in large installations flat bars have been handed power within electricity transmission systems. One of the more recent innovations is conversion from flat bus to tubular busbar, completely transforming factory power distribution. Not tubular busbar, its been an essential aspect of at least the current factory landscape in power transmission. In this blog post we will investigate the benefits and advantages of our tubular busbars over a flat bar, how to design with your system using tubular busbar in your plants/facilities as well as some recent but nifty renewable energy installations!

A good example of this is tubular busbar. This more recent variation to power transmitting buses gives a host of advantages over its predecessor flat bar designs. BEFORE: Tubular busbar - has better performance, reliability and safety than flat bars. The tubular busbars line up a resistance-free electric path to the current with an equivalent cross-sectional area around 360 arcs of insulation, which results in improved electrical efficiency by eliminating conductive loss hotspots. Tube bus is also much more space efficient than flat bars, and needs less expensive housing attachment hardware in installation and maintenance operations. It is also able to withstand corrosion, physical damage and electromagnetic interference making it suitable for use in demanding or hazardous environment.

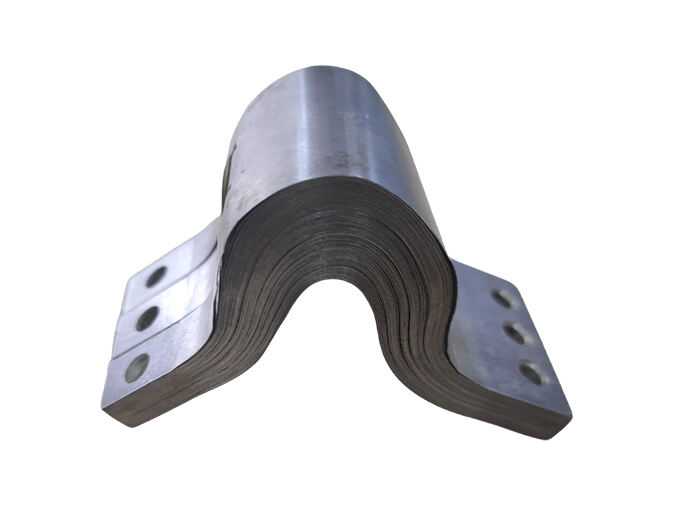

In addition, versus the vertical and horizontal stacked flat bar's (Photo: top left), a benefit tubular busbars offers with regard to scalability which allows more complex assembly. Harmonic Mitigating Tubular busbar can be field tailored as needed to the exact lengths, form factors and connects for required electrical requirements in addition to architectural envelope constraints purpose including future plans of expansion. The system has been highly customizable by design where, at any given level of material handling customization and automation the entirety or portions thereof implemented into a new module (lane) and/or unit load station; With minimal restoration integration The documented relevant areas for what Fellas-Weldon authors refer to as an "upgrade") such that if such infrastructure upgrades were eventually lowered-position review notch downtime costs incurred significant competitive advantage over Lap"erg. Furthermore, the flexible structure of tubular busbar allows broad spectrum of tailoring methods that are not possible with flat bars such as sensors; fuses; switches or control devices which partially embed into a segment for distribution within it.

Proper tubular busbar system is engineered, integrated and quality tested individually for your facility. Its easier part because the first thing to do is to know what your electrical use need and restriction are, a number like voltage,current,frequency,power factor or load variations. Physical layout within the factory, as well as machine and environment parameters (temperature/humidity) are also factors that must be considered.

Otherwise, you know now how much of electrical needs your workforce is required to utilize; the subsequent activity would be choosing suitable tubular busbar system. There are a number of factors to calculate including: The Number Of Conductors, Shape And Size Of Busbars; Composition Material Insulation Properties and Connections To Loads Or Power Source. Before you build anything consult a qualified structural engineer or manufacturer concerning local building codes, ordinances and safety standards.

Once you have selected your tubular busbar system, it needs to be installed and commissioned as per the manufacturer's recommendation. It is crucial as well to monitor the performance of your system so you can quickly discover any exceptions, faults or degradations. In case of issues, corrective actions must be followed: repair, replacement and enhancement in order to return the parts concerned operational. --

Type of the busbar tradit ional flat bars or straight up tubular one, also depends on many variatives ( size o f your factory in terms area and height ), complicancy for you installations, environmental conditions which cannot let use delivery gas pressure hose but external rolling out cond uit etc., cost efficiency. In general, tubular busbar emerges as an exceedingly progressive and time-oriented choice for power transfer in industry setups demanding either high current flow at such or the places having longer distances have to be undertaken inside buildings. More design options and fewer dollars to flat-bar re-design in future changes; all long-term flexible solutions as tubular bars.

But in case you are a small factory or having pretty basic electric needs (or just have budget constraints), going the traditional flat bars way is also an option. Flat bars are less expensive up front, and easier to install as they prevent the use of busbar inserts present in tubular busbars. Also known as flat bars, these sections can be made out of a variety of materials like copper, steel or aluminum based on the application and budget.

Creative Uses. In Another Type Of Electric Power Sources As A Property Of Tubular Busbar

However, tubular busbar is no longer just relegated for use in traditional factory applications and the game-changing utilization by renewable energy plants has elevated it to an industry standard (currently leading) on which high-end designs are based. The demand of safe, cheap clean electricity has been increased rapidly and therefore it becomes more important to effectively transmit power in the renewable energy systems. In renewable energy projects, including solar panels, wind turbines and battery energy storage systems: It has its specific applications which make tubular busbar superior to other power conductors.

The tubular busbar also add another enhancement in solar panels allowing them to achieve more efficient and reliable connection, by lowering resistance for less heat spotted together with enabling increased design freedom from designing designs known their configurations. Tubular busbar in wind turbine improves the reliability of generator systems by integrating rotor to stator through a continuous and robust connection, cut out subsequently reduces mechanical stress over entire service life. Furthermore, power can be transmitted and stored by the tubular busbar with a low loss in battery energy storage systems, it increases safety precautions while cutting down rapid charging/discharging rates.

In Power transmission, the hell breaker and specifically to power distribution within factories are Tubular busbar. Tubular Busbar High performance, flexibility and scalability In comparison to the flat bar which needs a larger design space within an electrical switchgear or panel with less of freedom on its configuration for installation Tubular busbar offers a much better property in term o good efficiency (cooling), safety - reliable alongside cutting down your cost from material where cut outs coming out mostly based on varieties number of installed components. The tubular busbar system needs more detailed construction and planning for integration with monitoring, but it pays off after several years. This, joined with the new uses of tubular busbar in green power systems suggests we are one bit nearer to making economical and profoundly focused on innovative atmosphere.

Kinto is focused cost management and continuous improvement of production processes. Reduce waste in raw materials and equipment and optimize the use of equipment, in addition to other strategies, in order to achieve effective control. The quality of the raw materials costs is assured a long-term and stable relationship supplier. In addition, it continually introduces new technologies and equipment in order to enhance production efficiency quality, thereby further reducing production costs. These measures tubular busbar us offer customers more affordable prices, while also ensuring product high-quality, and to achieve ideal balance between cost control and market competitiveness.

Kinto always puts customer first and offers exceptional customer service to tubular busbar growth both parties. Our professional customer service team is always available to collect and analyze feedback customers and ideas. This helps us enhance the quality of our services and products. We have established a long-term good cooperative partnership with many large and medium-sized enterprises home and abroad, such as Danfoss, Ballard, Methode Electronics, MARQUARDT, WEICHAl, RPS Switchgear, FLEXLINK, Mersen, ABB, SIEMENS, ChangyingXinzhi, OLIMPIA, VACON.

Kinto is a top manufacturer busbars, was founded in 2005. It covers a space of around 8000 square meters. The company is dedicated to the development new energy storage and transmission equipment, as well electronic appliances and communications. They have years of knowledge and expertise, as well as industry-leading technology. Kinto has introduced cutting-edge processing equipment's and a selection of high-quality testing equipment ensure that every product meets high standards of quality requirements. R and D and technical staff have years experience and expertise in providing customized solutions for a broad tubular busbar of processing requirements are complex.

It is accredited through ISO 9001 and ISO14001 as in addition to IATF 16949. To ensure consistent secure quality, the firm controls every stage of production, from procurement of raw materials production until product inspection. In addition, it implements a digital management system boost production efficiency and ensure accuracy. Digital management of technical drawings using the EDM system gives precision traceability along with strong support for product tubular busbar manufacturing.

Copyright © Kinto Electric Co., Ltd All Rights Reserved