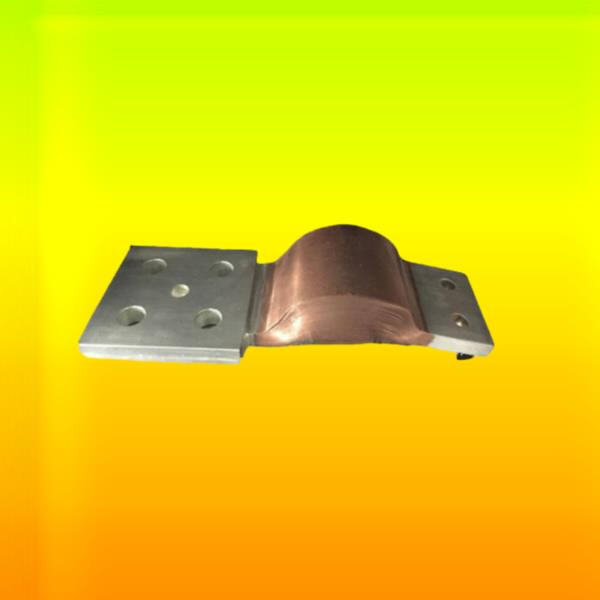

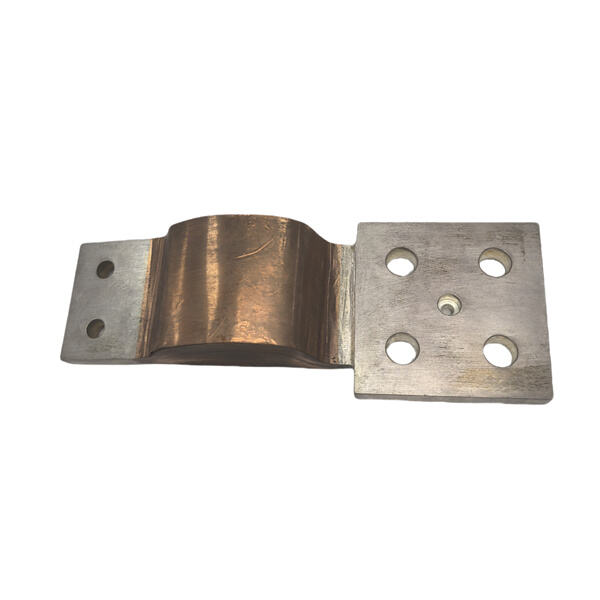

For electrical systems, copper shunts are crucial as they help these systems to move more current. But what exactly is a shunt? A shunt is a piece of equipment that connects the various areas in a circuit where electricity flows. Laminated Flexible Copper Shunts: a less early, much upgrade of these devices that improvement in presentation.

These special shunts are fabricated from multiple layers of copper bonded together with insulating kinto small busbar between each layer. That design in particular, allows the shunt to carry more current and keeps cooler than a solid copper one. Its a crucial part because of having more layers in the laminated shunts and thus can handle much more electrical flow without overheating, which is very important to perform efficiently.

The most significant selling point of laminated copper shunts is that they are highly reliable. One is, they function consistently and do not break easily. Usually, shunts have a wide surface where an electric current can flow quite freely and steadily. This is critically useful, in transportation industry and generation of energy among other lines. Whether in the field of sports, cars, bikes or machinery that requires maintenance and repair it is essential an electrical connection safe to ensure peak performance at great distances without causing accidents.

Copper laminated shunts are very versatile and can be used for many different applications. These are created and utilized in high-power electrical systems like renewable energy (solar or wind power), electric vehicles. Connectors for brake systems, high-intensity light sources and engine control kinto 600 amp bus bar are standard components of these lines where a good connection is particularly important.

Moreover, laminated copper shunts is also used for link between batteries or any other power storage devices. This is because they can switch high current, an essential parameter when interconnecting higher power kinto 400a busbar. They provide a heavy-duty secure mounting of your battery and link to the rest of its wires. This make sure that the power is utilize in an impactful and purposeful manner.

Laminated copper shunts also enhance electrical flow and assist existing electrical systems to carry more current. Since copper has multiple layers solar battery bus bar provides a larger surface area to come in contact with electrical current. When the surface area is larger, there are more pathways for electricity to flow through its electrical conductivity improves.

A additional surface area to also allow the shunts to dissipate more heat. In high-power scenarios, however, heat can become a major concern too much of it put out by electrical components will cause problems and ultimately destroy circuit breaker panel bus bars. In this way, the use makes laminated copper shunts more suitable for high-power applications that could otherwise lead to heat build-up in H-Bridges.

It is accredited through ISO 9001 and ISO14001 along with IATF 16949. To ensure consistency and reliability quality, the company oversees each step of the process, from procurement of raw materials to production, to inspection products. The company also implements a digital management system boost production efficiency and accuracy. The digital administration technical drawings using the EDM system ensures the accuracy and reliability drawings. It also provides solid Laminated flexible copper shunts for product development and production.

Kinto is focused on cost control Laminated flexible copper shunts through continual optimization of production processes. Reduce the waste of equipment and raw materials and optimize use of equipment, among other measures, to achieve effective control. The long-term and steady cooperation suppliers assure the viability of procurement costs for raw materials. The company also continuously introduces new production technologies and equipment in order to improve the quality and efficiency of processing products, and thereby reduce production costs. We can offer customers cheaper prices, whilst ensuring the highest quality. This is a win-win situation for cost control competitiveness.

Kinto always places the customer first offers exceptional customer service in order to create a win-win situation. Kinto has a Laminated flexible copper shunts customer service department will constantly collect customer opinions well as suggestions to improve the quality of services products. We have established a long-term and good cooperative partnership with many large medium-sized enterprises at home and abroad, such as Danfoss, Ballard, Methode Electronics, MARQUARDT, WEICHAl, RPS Switchgear, FLEXLINK, Mersen, ABB, SIEMENS, ChangyingXinzhi, OLIMPIA, VACON.

Kinto is a top manufacturer busbars, was founded in 2005. It covers a space of around 8000 square meters. The company is dedicated to the development new energy storage and transmission equipment, as well electronic appliances and communications. They have years of knowledge and expertise, as well as industry-leading technology. Kinto has introduced cutting-edge processing equipment's and a selection of high-quality testing equipment ensure that every product meets high standards of quality requirements. R and D and technical staff have years experience and expertise in providing customized solutions for a broad Laminated flexible copper shunts of processing requirements are complex.

Copyright © Kinto Electric Co., Ltd All Rights Reserved