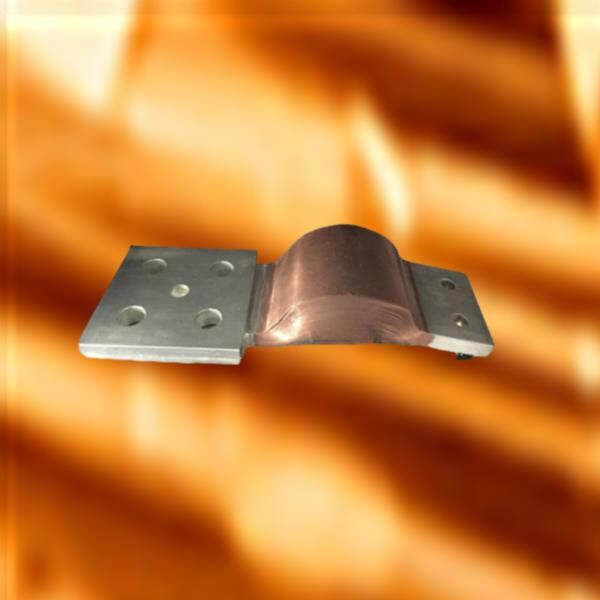

Laminated Copper Shunts: Laminated copper shunt is a distinct metal that plays an important role in the realm of electricity. These are composed of copper in thin layers that are then encased with substances including plastic films. That unique construction makes them work great in a lot of electrical applications.

Laminated copper shunts are great for large machines like big construction equipment or powerful generators, where they will never be overloaded with electricity. They are very useful because they make electricity pass through easily and with great efficiency. Certainly a lot of electricity can flow through them without getting too hot, which is very important when you deal with heavy machinery. When a shunt heats up too much, it can become defective and lead to issues; however, cop laminated copper is designed specifically for the opposite purposes so that any excessive heat produced during these power-demanding situations will not be an issue.

Electricity has a way of jostling about in a wire which can move slow (fast) and create heat. This resistance is called slowing down. Reverse cycling can consume extra energy and result in various problems which could make it difficult for a machine to function optimally. However, this problem can be easily mitigated in the case of laminated copper shunts. This makes the current travel easily and swiftly as currents always want to take an easy route. What that does is it allows those machines to be better, and utilize energy more efficiently.

The key to these laminated copper shunts, is just simply how they are produced. The manufacturer stacks the thin layers of copper layer by layer and places the surrounding materials that cover them, not much different from preparing a sandwich. This specific layering, however allows electricity to flow effectively through the copper layers. Electricity, moving through the shunt will simply pass along smoothly throughout the copper without having to encounter any pile up by insulating materials. It is this construction that explains why laminated copper shunts are so beneficial in their function.

These laminated copper shunts are increasingly being used in several industries because of their usefulness. They are found in many places — e.g. heavy machines, large power generators or a microwaves and washing machine used to daily chore biomass stands amazingly! As they exhibit very little resistance in transmitting electrical charge, superconductors play a key part in technologies of our age. Engineers and scientists keep on searching for laminated copper shunts, which can be utilized in the design of electrical systems to get better results.

Kinto is a renowned manufacturer of busbars, was created in the year 2005. It covers a space of around over 8000 square metres. The company is dedicated to the development of new energy storage and transmission equipment along with electronic appliances and communication. They have years of knowledge and experience, as well as the most advanced technology. The company has invested in modern processing equipment's and various testing tools that are precise in order to ensure that each product meets the highest standard of quality. R and D and technical experts have deep expertise and practical experience for providing custom laminated shunts copper to meet a wide array of demanding processing requirements.

Kinto focuses on cost control improvement by constant optimization of manufacturing processes. Reduce the amount of waste generated by raw materials and equipment and increase the efficiency of equipment, in addition to other things, to ensure effective control. The long-term steady laminated shunts copper with suppliers assures the viability of raw material procurement costs. Also, it is constantly introducing new technologies and equipment increase the efficiency of processing and quality of the products and reduce production costs. We able to offer our customers cheaper prices, while ensuring product quality. This is win in terms of cost control and competitiveness.

It is certified by ISO 9001 ISO14001 as and IATF 16949. The company is able control each connection from the procurement of raw materials through production to final product inspection to ensure stable reliable quality of product. Furthermore, the laminated shunts copper implements a management system is digital to boost efficiency in production and ensure accuracy. The management of technical drawings digitally via EDM system offers transparency and precision in addition to providing solid support for development and manufacturing.

Kinto always prioritizes needs of its customers and offers exceptional customer service to create a win-win situation. A professional customer service team is hand to laminated shunts copper and analyze customer feedback and suggestions. This helps enhance the quality of our services and products. We established a long-term and good cooperative partnership with many large and medium-sized enterprises at home and abroad, such Danfoss, Ballard, Methode Electronics, MARQUARDT, WEICHAl, RPS Switchgear, FLEXLINK, Mersen, ABB, SIEMENS, ChangyingXinzhi, OLIMPIA, VACON.

Copyright © Kinto Electric Co., Ltd All Rights Reserved