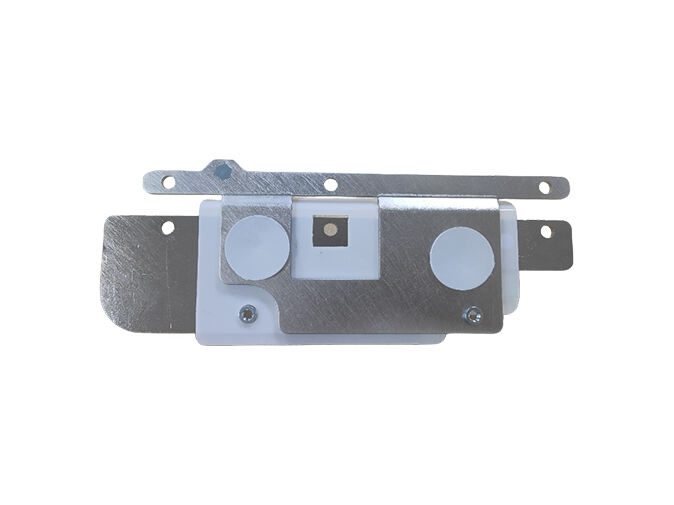

Ini merupakan bagian tersendiri dari mesin listrik, Pin Busbar bekerja dengan dua cara: membawa arus dari satu tempat ke tempat lain dan menciptakan tegangan pada via-via. Ini dilengkapi dengan banyak pin yang terhubung ke berbagai bagian sistem dan memungkinkan aliran daya mengalir sesuai dengan normal. Pin-pin tersebut diatur dalam bentuk tertentu untuk mencegah aliran listrik, sehingga percikan juga dapat diminimalkan (bunyi fisik).

Ketika Anda mempertimbangkan untuk memasang Pin Busbar, selalu ada lebih banyak keputusan yang harus diambil, dan faktor-faktor yang memerlukan perhatian Anda. Pertama, Anda bisa mendapatkan pin-pin untuk menyusun diri mereka sendiri dalam cara yang seharusnya memungkinkan kinerja optimal. Jika Anda perlu sedikit lebih hati-hati dalam perencanaan dan mengukur bagian-bagian tersebut, itu tidak akan terlalu sulit. Penyelarasan yang tepat sangat penting untuk memastikan aliran daya listrik yang baik.

Pin Busbars memiliki banyak keuntungan yang membuatnya cocok digunakan dalam sistem listrik. Dan jelas, salah satu hal utama yang kita dapatkan darinya adalah transmisi daya jarak jauh secara aman dan efisien. Ini menjadi lebih signifikan karena menghemat Anda dari membuat banyak koneksi kompleks yang dapat merusak performa ketika skala diperbesar (dalam gedung atau fasilitas).

Lebih kuat dan tahan lebih lama: Ini adalah keuntungan esensial lain dari Busbar Pin. Oleh karena itu, mereka dapat diandalkan untuk bekerja di luar dalam kondisi iklim yang keras. Mereka juga dirancang untuk bekerja dalam kondisi kerja berdebu dan kotor sehingga mereka dapat berfungsi hingga akhir. Hal ini akan memungkinkan mereka bertahan lebih lama, dan performa seiring waktu dalam lingkungan keras kurang mungkin mengalami degradasi.

Busbar Pin akan dirancang berdasarkan setiap fungsi tertentu dalam konfigurasi yang berbeda. Sebagai contoh, beberapa Grid Magnetik digunakan untuk aplikasi tegangan rendah dan yang lainnya dirancang untuk memenuhi kebutuhan khusus aplikasi tegangan tinggi dengan grid magnetik. Sebagai hasilnya, mereka mampu memenuhi kebutuhan listrik yang beragam di berbagai aplikasi.

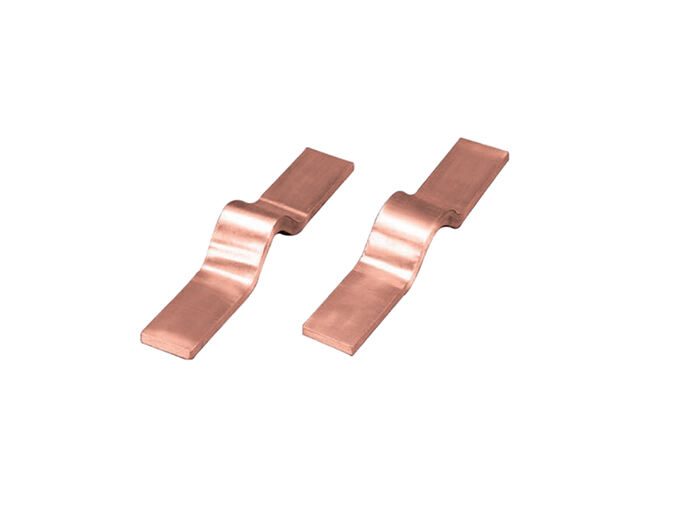

Terakhir, bahan dari mana Pin Busbars diproduksi juga dapat bervariasi. Kabel tahanan yang lebih besar yang diproduksi melalui kabel televisi lebih baik dalam menghantarkan listrik, karena tembaga memiliki tingkat konduktivitas yang sangat tinggi -- jadi meskipun kawat tahanan yang lebih besar kemungkinan akan menggunakan kabel tembaga, yang lain mungkin terbuat dari aluminium. Bahan, apa pun jenisnya, harus sesuai dengan spesifikasi individu yang diperlukan agar sistem berfungsi dengan benar.

Untuk menjaga agar Pin Busbar tetap bekerja dengan baik, pemeriksaan dan pembersihan secara teratur sangat penting. Ketika Anda melakukan ini secara konsisten, itu akan membantu memastikan bahwa pin-pin tersebut sejajar dengan benar dan tidak ada sambungan yang longgar atau menghalangi operasi optimal. Hal ini sangat penting untuk memastikan fungsi pemrosesan yang tepat, dan demi alasan keamanan.

Kinto selalu merupakan perusahaan yang berfokus pada pelanggan dan menawarkan layanan pelanggan luar biasa guna mencapai pertumbuhan saling menguntungkan. Departemen layanan pelanggan kami sangat menghargai umpan balik pelanggan serta senantiasa siap menerima dan menganalisis ide-ide masukan dari pelanggan. Hal ini membantu kami meningkatkan produk dan layanan kami. Kami telah menjalin kemitraan kerja sama jangka panjang dan positif dengan banyak perusahaan besar dan menengah di dalam maupun luar negeri, seperti Danfoss, Ballard, Methode Electronics, MARQUARDT, WEICHAI, RPS Switchgear, FLEXLINK, Mersen, ABB, SIEMENS, ChangyingXinzhi, OLIMPIA, dan VACON.

Kinto berfokus pada peningkatan manajemen biaya melalui optimasi berkelanjutan terhadap proses manufaktur. Mengurangi jumlah limbah yang dihasilkan oleh peralatan dan bahan baku serta meningkatkan efisiensi peralatan, di antara strategi lainnya, untuk mencapai kontrol yang efektif. Hubungan kerja sama jangka panjang dan stabil dengan pemasok menjamin kelayakan biaya pengadaan bahan baku. Selain itu, perusahaan secara terus-menerus memperkenalkan teknologi dan peralatan produksi baru yang meningkatkan kualitas efisiensi produksi dan mengurangi biaya produksi. Hal ini membantu kami menawarkan harga yang lebih terjangkau kepada pelanggan sambil mempertahankan kualitas produk serta mencapai keseimbangan optimal antara pengendalian biaya dan daya saing pasar.

Perusahaan ini terakreditasi melalui ISO 9001 dan ISO 14001 serta IATF 16949. Untuk memastikan konsistensi dan kualitas yang andal, perusahaan mengawasi setiap tahap proses, mulai dari pengadaan bahan baku hingga produksi dan pemeriksaan produk. Perusahaan juga menerapkan sistem manajemen digital untuk meningkatkan efisiensi dan akurasi produksi. Administrasi digital gambar teknis menggunakan sistem EDM menjamin akurasi dan keandalan gambar. Sistem ini juga menyediakan busbar pin solid untuk pengembangan dan produksi produk.

Kinto adalah produsen terkemuka busbar, yang didirikan pada tahun 2005. Perusahaan ini menempati area seluas sekitar 8.000 meter persegi. Kinto berkomitmen pada pengembangan peralatan penyimpanan dan transmisi energi baru, serta peralatan elektronik dan komunikasi. Perusahaan memiliki pengalaman bertahun-tahun serta keahlian dan teknologi terdepan di industri. Kinto telah menghadirkan peralatan pemrosesan mutakhir dan berbagai peralatan pengujian berkualitas tinggi guna memastikan setiap produk memenuhi standar kualitas yang tinggi. Staf penelitian dan pengembangan (R&D) serta staf teknis memiliki pengalaman dan keahlian bertahun-tahun dalam menyediakan solusi yang disesuaikan untuk berbagai kebutuhan pemrosesan busbar pin yang kompleks.

Hak Cipta © Kinto Electric Co., Ltd. Hak Cipta Dilindungi