The effectiveness of the system, particularly in modern times of industrialization (together with a review on how electricity assist here), is also emphasized. Therefore, it is essential that the staff responsible for ensuring operations continue to run smoothly (electricians and engineers) ensure electrical infrastructure availability. The distribution system contains a device named the busbar which is used in buildings to get high amount of electrical power arrived from places. Although many types of busbars exist, the 1000 amp are most common in industry because they have to handle a lot of power applications. The steps to install a 1000 amp busbar are as follows:

* Punch list before the 1000 amp busbar installation can commence, a layout of what electrical loads will be connected to your system must be hashed out. All this careful planning will make it so the busbar is properly sized to handle power requirements for that building. You will also need a professional installation as mistakes can be pricey or even dangerous. The next step is to determine where you will be locating the busbar when installing. It is better to look for such a central position that it will be always easy and convenient for you to maintain in, if the necessities demand. In addition, the grounding of busbar must be reasonable in order to avoid electrical accidents.

* Most notably, a 1000 amp busbar is able to handle so much power in an area where many applications are high powered. The busbar can satisfactorily meet the high-power demand required in powering large machinery and industrial equipment. It also lowers the risk of voltage drops which in turn ensures a more efficient system.

Flexibility - The 1000 amp busbar Customizing the busbars can make them tuned exactly for any specfic needs within a plant, and save huge money later on because only that much is being used.

The 1000A busbar system should be properly inspected from time to another in order that it may last much longer with none major performance issue and any fuel packages which can result well in advance.grp49. These may be a look at the busbar inside and listen for any abnormal activity, I.e. fan sounds or heat etc Similarly an unsoiled busbar which does not have any fragments hindering it, is mandatory if you want to avoid nodal inefficiency.

Busbar problems can always be handled by a professional service. Better keep in mind that such incidents might occur with busbars and never do the odds of it at all. Find a way to measure the voltage, verify connections, and perhaps investigate your grounding system.

Obviously, in selecting a 1000 amp busbar price is as robust of a factor to consider here like any other aspect. They are so conductive or similar in electric propertiesCuper that prevention is more expensive, this due to its bothconductivethat they are cheap.Immutable

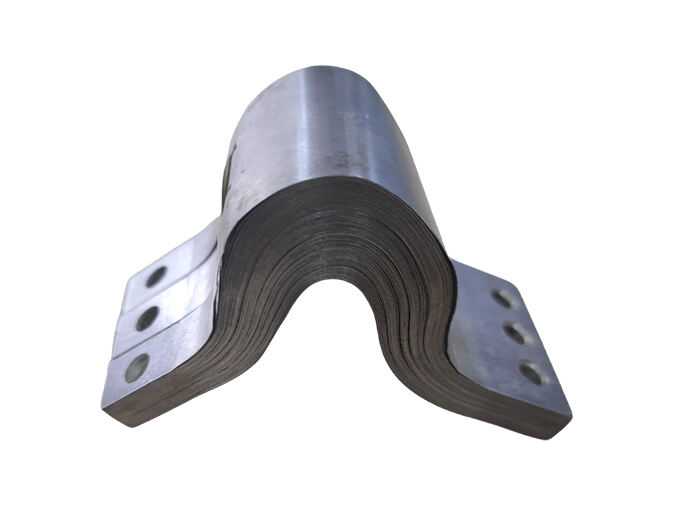

Copper Busbars - If efficiency is vital in industrial environments, copper bus bars are the best choice since copper has a good electrical conductivity. However, as for the more expensive copper these is for installation costs. Nonetheless, aluminum bus bars save cost comparing to copper and can be used for good conductivity but it is possible that required further maintenance or care in the long run.

Rising renewable energy and electric vehicles to create new opportunities in use of 1000 amp busbars Busbars, for example, are utilized to connect harvesting equipment like solar panels and wind turbines with the electrical grid in order to create a smooth system of power distribution.

For instance, in electric vehicle charging stations; bus-bars are being introduced as a means of rapid charging power distribution and henceforth time taken for the process of electrical vehicles getting charged gets reduced.

Summary: A number of the most typical elements in industrial and commercial electrical infrastructure may be rated at 1000 amp or a busbar. Installing and servicing drives in accordance with best practice also makes for more consistent performance. Moreover, one can have the best cost-effective and efficient busbars from it which suits that specific installation in all sense. In the end, demand for renewable energy and electric vehicles are creating new plays on 1000 amp busbars that provide a green-glowing look into what is ahead in our global sustainable-energy future.

Kinto is a leading busbar manufacturer was founded in with a total area of 8000 square meters with a commitment innovative energy storage Transmission and distribution including electronic appliances and communications using the most advanced technology in the market as well as a vast production history. Kinto has developed advanced processing equipment's, as well as a wide range of testing tools that are precise to ensure each product meets high standards of quality standards. The R and D team and the technical team extensive know-how and have extensive experience providing 1000 amp busbar solutions to a range complex processing requirements.

It is accredited through ISO 9001 and ISO14001 as in addition to IATF 16949. To ensure consistent secure quality, the firm controls every stage of production, from procurement of raw materials production until product inspection. In addition, it implements a digital management system boost production efficiency and ensure accuracy. Digital management of technical drawings using the EDM system gives precision traceability along with strong support for product 1000 amp busbar manufacturing.

Kinto is constantly focusing on customers and offering superior customer service that will result in the goal of a win-win for everyone. Our professional customer service team is on hand to gather and analyze feedback from customers suggestions. This allows us to improve the 1000 amp busbar of services and products. We have established a long-term and good cooperative partnership many large and medium-sized enterprises home and abroad, such as Danfoss, Ballard, Methode Electronics, MARQUARDT, WEICHAl, RPS Switchgear, FLEXLINK, Mersen, ABB, SIEMENS, ChangyingXinzhi, OLIMPIA, VACON.

Kinto is focused on cost control continuous improvement of manufacturing processes. Reduce the amount of waste generated raw materials and equipment, and enhance the efficiency of equipment, in addition to other things, to ensure efficient control. A long-term, stable and reliable relationship with suppliers will ensure the efficiency in procurement of raw materials. We also constantly introduce 1000 amp busbar production methods equipment to enhance the efficiency and quality of processing of the products decrease production costs. Our customers can enjoy better prices, while maintaining product quality. This is a win in terms cost control and competitiveness.

Copyright © Kinto Electric Co., Ltd All Rights Reserved