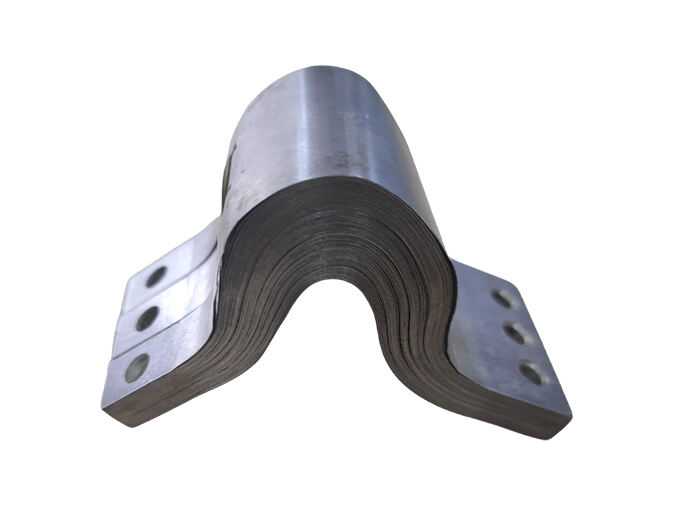

A busbar for 3 phase is a key part of any power network. A metallic bar that is used to carry current between moving parts in gears, etc. This electricity used to travel through the busbar which makes power for other regions in a 3 phase system, making the whole of this system work correspondently and effectively This is because the electrical system as such would lack the power distribution, which must be so that machines and devices can work properly.

The busbar must withstand the heat changes and stress from conducting electricity, in addition to its size. This implies that the materials must be strong enough to tolerate both heating by current, and also any mechanical stresses generated during operation. Selecting the ideal material and manufacturing process are critical to ensuring that a busbar performs reliably for many years.

Better efficiency can be expected in this regard if the electrical system is designed to run on 3 phase busbars. These busbars can transport electricity more efficient than other methods of delivering it, and often include solutions that can contribute to energy savings or material waste reductions. Cutting down on wasted electric power is always a good thing for the environment and the bank account so if energy efficiency can be improved than that works in our favor.

In addition, 3 phase busbars enable a more precise management of the power supply. This control keeps things functioning properly which will lower the amount of repairs needed and you can avoid paying for damages to be repaired. By having a three phase busbar in place businesses can run so much more effectively and that means improved productivity and fewer stoppages.

Using 3 phase busbars in an electrical system come with both good and bad things. The positive about this is that they can still hold a ton of electricity, which makes them excellent for heavy businesses and factories as those need an abundant amount to operate there machines. Their ability to deliver power loads make them extremely valuable in heavy industrial environments.

One downside is they may require a significant investment in the installation and care. Cost of investment will be high for buying and installing 3 phase busbar system, so you need to plan accordingly before making a decision. If you are considering using 3 phase busbars, it would be wise to consider the pros and cons carefully. That way you can make an informed decision on what is right for your specific electric system.

Your 3 phase busbars are an electrical system, which means it will have its fair share of issues sometimes that need to be resolved. This type issue is due to loose connection,over heat and damage of insulation between bus bar.. Poor electrical performance due to loose connections and potentially severe damage from overheating This can pose safety hazards and trigger system failures if ever the insulation is damaged.

Kinto is focused on cost control continuous improvement of manufacturing processes. Reduce the amount of waste generated raw materials and equipment, and enhance the efficiency of equipment, in addition to other things, to ensure efficient control. A long-term, stable and reliable relationship with suppliers will ensure the efficiency in procurement of raw materials. We also constantly introduce 3 phase busbar production methods equipment to enhance the efficiency and quality of processing of the products decrease production costs. Our customers can enjoy better prices, while maintaining product quality. This is a win in terms cost control and competitiveness.

Kinto is constantly focusing on customers and offering superior customer service that will result in the goal of a win-win for everyone. Our professional customer service team is on hand to gather and analyze feedback from customers suggestions. This allows us to improve the 3 phase busbar of services and products. We have established a long-term and good cooperative partnership many large and medium-sized enterprises home and abroad, such as Danfoss, Ballard, Methode Electronics, MARQUARDT, WEICHAl, RPS Switchgear, FLEXLINK, Mersen, ABB, SIEMENS, ChangyingXinzhi, OLIMPIA, VACON.

It is certified through ISO 9001 and ISO14001 as along with IATF 16949. The company strictly control every link raw material procurement through production to final product inspection to ensure stable reliable quality of the product. In addition, it implements a digital 3 phase busbar system boost efficiency production and precision. The management technical drawings digitally with the EDM system ensures highest level of traceability and accuracy in addition to providing solid support for product development and manufacturing.

Kinto is a renowned manufacturer of busbars, was founded the year 2005. It has a total area of over 8000 square metres. The company is dedicated to the development of revolutionary energy storage transmission products in addition to electronic appliances and communication. They have a wealth experience and industry-leading technology. Kinto has invested in the latest processing equipment's various testing tools that are precise in order to ensure each product is of the highest standards of quality. The R and D team and technical staff have 3 phase busbar expertise experience in providing customized solutions for a variety of processing needs that complex.

Copyright © Kinto Electric Co., Ltd All Rights Reserved