Electricity becomes hot and become slower to pass through a wire. This heat will reduce the efficiency of your electricity system (hence it won't work as good like before). Yet, an energy is unusually able to well up. if you take advantage of the high power busbar in that case and then the electricity will be able shoot a lot faster therefore conduct more satisfactorily as manipulated by those circuits. This is extremely necessary for smooth functioning of all processes.

A high power busbar is like a very thick, strong wire that can carry lots of electricity without getting too hot. Plasma is typically formed from materials such as copper or aluminum that conduct electricity well. High power busbars have a high voltage and are responsible for spreading electricity throughout an entire building or factory, which is key to providing each tool with the right amount of electrical flow.

High power busbars have many advantages in a factory, which makes them highly beneficial. For one, they make electricity flow to more efficiencly as th e=i input less heat. The reason why this is vital because it ensures that you can cut on costs by reducing the amount of power being used to drives machines and other equipment. Energy is one of the biggest costs for a factory, so when that cost becomes cheaper — Holy Moly!

A second point is that high power busbars take any less space than traditional wiring systems. This is a big plus as it simplifies would be more efficient factory designs. This makes the factory easier to naviage and operate since there is fewer clutter from wires. Also, as the high power busbars are strong and so have lesser chances of breaking than normal wires. This durability, in turn, results in less frequent repairs and maintenance — a significant cost saving.

Picture high power busbars like a giant jug of water, to get an idea about how they operate. The next thing I learned is if you pour that water too fast, it can spill everywhere and make a HUGE mess. But pour it with lightening-speed and you fill a cup very soon. That's like what happens with current in a wire. A thin wire simply cannot carry all of the electricity you force through it and will begin to heat up if too much current passes.

A major positive upside to high power busbars is how they simplify factory design. Common Wiring systems- The most traditional wiring system can take up a huge amoount of space (two plumbers) and sometimes they are almost impossible to lay, especially in dwarfs or complex layouts. 2] It is a difficult problem to solve for production system designers.

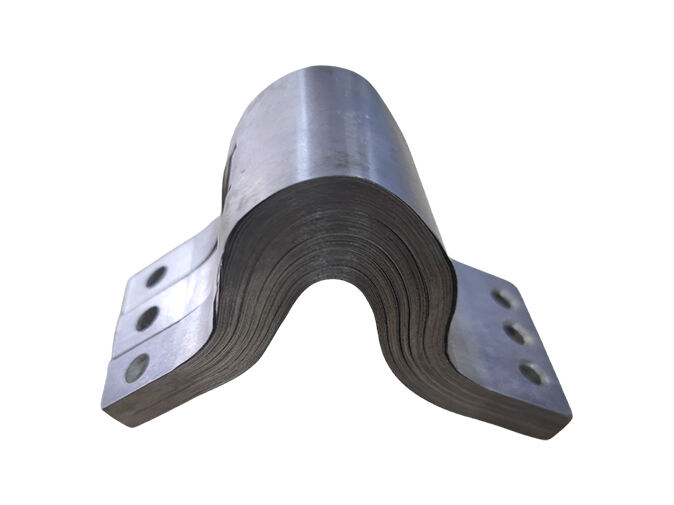

However, there are flexible high-power power busbars that can fit in at odd places. They can also be bent around corners or curved objects, so they are very versatile. The design itself is optimized, to allow designers to use the same space efficiently and minimize waste of this resource. The busabaars with high power allow factories to be designed effectively and without losing any precious space.

Kinto focuses on cost control improvement by constant optimization of manufacturing processes. Reduce the amount of waste generated by raw materials and equipment and increase the efficiency of equipment, in addition to other things, to ensure effective control. The long-term steady high power busbar with suppliers assures the viability of raw material procurement costs. Also, it is constantly introducing new technologies and equipment increase the efficiency of processing and quality of the products and reduce production costs. We able to offer our customers cheaper prices, while ensuring product quality. This is win in terms of cost control and competitiveness.

Kinto always places the customer first offers exceptional customer service in order to create a win-win situation. Kinto has a high power busbar customer service department will constantly collect customer opinions well as suggestions to improve the quality of services products. We have established a long-term and good cooperative partnership with many large medium-sized enterprises at home and abroad, such as Danfoss, Ballard, Methode Electronics, MARQUARDT, WEICHAl, RPS Switchgear, FLEXLINK, Mersen, ABB, SIEMENS, ChangyingXinzhi, OLIMPIA, VACON.

It is accredited through ISO 9001 and ISO14001 along with IATF 16949. To ensure consistency and reliability quality, the company oversees each step of the process, from procurement of raw materials to production, to inspection products. The company also implements a digital management system boost production efficiency and accuracy. The digital administration technical drawings using the EDM system ensures the accuracy and reliability drawings. It also provides solid high power busbar for product development and production.

Kinto is renowned manufacturer busbars, was established in 2005. It covers an area of 8000 square meters. The company is dedicated to the creation innovative energy storage and transmission products addition to electronic appliances and communication. They have years of knowledge and expertise, as well as industry-leading technology. Kinto has developed advanced processing equipment's a variety of testing tools that are precise to ensure that every product meets highest standards of quality high power busbar. The R and D team and technical team have deep knowledge and experience in delivering custom solutions to a range of complex processing requirements.

Copyright © Kinto Electric Co., Ltd All Rights Reserved