How to Choose the Right Bus Bar for Electrical Systems

Bus bar is in essence a vital link part of any electrical system, it allows for better and uniform distribution of power. This is even more important at working 100 amp circuits. Before deciding, there are many factors which you must take into consideration because it can impact the performance of bus bar significantly.

Bus Bars - The Good, Bad and Ugly

The type of bus bar that is selected often depends on the application you wish to use it for. In practice, although a laminated bus bar is recommended for applications when the power requirements are significantly less-a bolted bussing system has its advantages. Understanding the difference will allow you to show yours according to your interests.

This means that the materials therefore can bear upon a vital spec in terms of using bus bar, as it will largely determine how robust they are when mechanically stressed/strained (i.e. pulled and sheared), their conductance compared with copper or even resistive to corrosion (%20engvironmental%20&%proteasantages). Among many materials, there are widespread uses of copper and aluminum as these were identified to have very good conductivity level along with least resistance which is also cost competitive. By learning more about each of the materials unique characteristics, you can help determine which is best for your needs.

Size; of 1the most straightforward considerations in a bus bar selection. You also need to select the properly sized one depending on how much voltage and currents there are in your system. Choosing the right size of bus bar is key because having a smaller one will likely overheat and cause damage, however choosing too large can be quite wasteful in terms of energy ultimately squandering space. You need to find out what works for you (each of us is unique, remember?).

Best Top Bus Bars for 100 Amp Circuits

In the world of 100 amp high power circuits not all fuse bus bars are created quality equally. For those applications, therefore, you would be well-served to select a purpose-built specimen if you want the reassurance of knowing that your bus bar is capable of keeping up. Top Rated Bus Bars in 2021

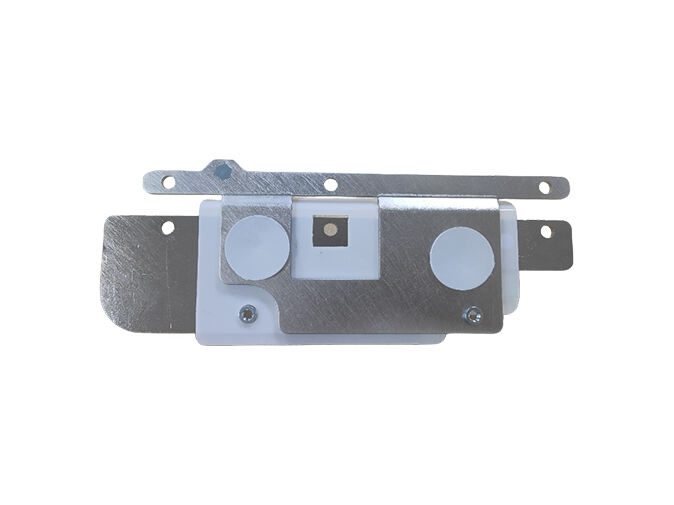

Blue Sea Systems 100A Bus Bar Like the other bus bar this is a good one to use for up to a 100 amp connection. Something with a good API or support for multiple connections.

WirthCo 20092 Battery Doctor Bus Bar with Stud (Rated up to 48 Volts and Maximum Of One Hundred Amps) This is just another basic, affordable one in aluminum materials. It is highly corrosion resistant and can be designed to accommodate several connections, making it suitable for varied size systems as used in Cast iron pipes.

BEP Marine 701 Bus Bar - Since designed for marine connections, rated to hive-ampere feed but beefy power and a tinned-copper base should be perfect even where being roughed up. These features, along with a small compact design and ease of installation make it very appealing.

Read: DIY tinkerers may work on your self-driving car RELATED_ESTORIES

If you also need to install 100 AMP Busbar yourself at home or re now working in an institution then there are some other features that must be present. Step 1: Choose an easy to install bus bar with a clear how-to installation so you have not need the equipment or skills. Finally, make sure that the bus bar material and size you choose are appropriate for how your system will be used.

Industrial surrounds is everything about effectiveness and a good electric system can do wonders here. Thus consolidating power distribution can also reduce the quantity of used and wasted energy by centralize it through 100 amp bus bar. The use that can deliver it at maximum capacity according to the voltage and current outputs.

This is because the casual wrongnesses that are circulating about these bus bars must be debunked so that you can make better decisions. Amperage is only part of the equation for selecting a bus bar. Knowing the material, size and voltage rating will help identify whether alternatives are necessary to avoid bad functionality or destructive accident which bus bars clearly state that they are different for a reason.

After knowing all these aspects, selecting an appropriate bus bar which can cater the needs will enhance your overall electrical configuration's performance & reliability.

Kinto focus on cost control efficiency enhancement, through continuous optimization of manufacturing processes, reducing wasted raw materials, and improve utilization of equipment, among other ways effective cost control. The competitiveness of the raw material costs is ensured by a long-term and stable relationship supplier. In addition, it also continually introduces new technologies and equipment order to enhance processing bus bar 100 amp and product quality and reduce production costs. These steps allow us to offer our customers better competitive prices while ensuring product quality and ideal balance between cost control and market competition.

Kinto is a leading busbar manufacturer was founded in with a total area of 8000 square meters with a commitment innovative energy storage Transmission and distribution including electronic appliances and communications using the most advanced technology in the market as well as a vast production history. Kinto has developed advanced processing equipment's, as well as a wide range of testing tools that are precise to ensure each product meets high standards of quality standards. The R and D team and the technical team extensive know-how and have extensive experience providing bus bar 100 amp solutions to a range complex processing requirements.

It is certified through ISO 9001 and ISO14001 in addition to IATF 16949. To ensure constant and reliable quality, the firm controls every aspect of the process from raw material procurement through production until product inspection. It also employs computerized management system that improves production efficiency and accuracy. The digital administration of technical drawings using the EDM system guarantees the accuracy and reliability of drawings. Provides an unbeatable support to product development and bus bar 100 amp.

Kinto always prioritizes needs of its customers and offers exceptional customer service to create a win-win situation. A professional customer service team is hand to bus bar 100 amp and analyze customer feedback and suggestions. This helps enhance the quality of our services and products. We established a long-term and good cooperative partnership with many large and medium-sized enterprises at home and abroad, such Danfoss, Ballard, Methode Electronics, MARQUARDT, WEICHAl, RPS Switchgear, FLEXLINK, Mersen, ABB, SIEMENS, ChangyingXinzhi, OLIMPIA, VACON.

Copyright © Kinto Electric Co., Ltd All Rights Reserved