Copper bus bars are key components in electrical systems. They facilitate the safe and efficient transmission of electricity. Copper functions as a powerful conductive that can ferry electrical current from point A to point B. It’s a great material for Kinto bus bars, because it allows electricity to flow effortlessly and can tolerate a great deal of heat without becoming too hot itself. This is why copper bus bar is durable and provides long-life to electrical systems.

Copper Bus Bars in Factories There are plenty of advantages to using Kinto copper bus bars in factories. They can carry a lot of electrical current with very little loss of energy, which makes them valuable for when you need a lot of electricity. Copper bus bars are also incredibly strong, allowing them to handle the harsh conditions of a factory floor. This strength helps to keep electrical systems operating well even when they are pushed to their limits.

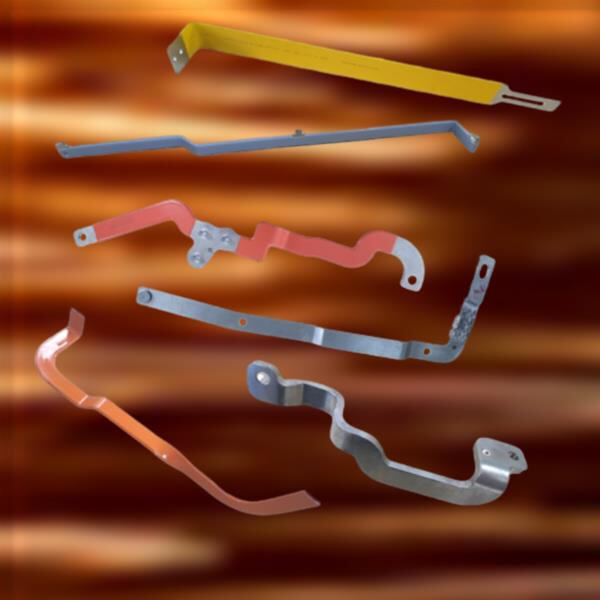

Copper bus bars are extremely versatile and can be used in a number of ways to distribute power. You may find them installed on switchgear, power distribution units and control panels. Copper bus bars ensure electric power is shared safely and also efficiently. Their ease of installation and customization make them a popular selection for various power systems.

One of the primary reasons to specify copper bus bars is that electrical systems take fewer days to work more efficiently and dependably. They have very low electrical resistance, so they can carry through electricity with minimal loss of energy. This makes systems more efficient, because less energy gets wasted. Further, electrical copper bus bar can dissipate the heat that accumulates in use, preventing overheating and promoting reliable electrical configurations.

There are a couple of reasons why Kinto bus bars are usually made from copper. Copper is a superior if not the preferred material for bus bars for many industries. First, it is a better conductor of electricity than other metals, which helps keep electricity moving without interruption. This lowers energy losses and helps systems operate more efficiently. Second, copper is sturdy and malleable, both traits that are useful in a rugged setting. It’s also rust- and heat-resistant for durability. Finally, flexible copper bus bar is in ample supply and relatively affordable, so businesses can take advantage of it to upgrade their power systems.

It certified by ISO 9001 and ISO14001 as and IATF 16949. To ensure consistent reliable quality, the company controls every step raw material procurement through production and inspection of product. Additionally, it Copper bus bar a digital management system to boost efficiency in production and accuracy. Digital management of technical drawings through the EDM system ensures accuracy traceability in addition to providing solid support for product development manufacturing.

Kinto is focused on cost control and improvement through continual optimization production processes. Reduce waste in raw materials and equipment, and improve the utilization of equipment, in addition to other methods, to attain an effective control. The long-term and steady cooperation with suppliers guarantees competitiveness of procurement costs for raw materials. In addition, it actively introduces advanced production Copper bus bar equipment to improve production efficiency and quality and reduce production costs. This allows us give customers affordable prices while still ensuring high-quality, and to achieve an ideal balance between cost control market competitiveness.

Kinto is top manufacturer of busbars, was founded in the year 2005. It covers an area of more than 8000 square meters. Kinto is committed to the development of new energy storage and transmission technologies along electronic appliances and communication. Kinto has a wealth of experience and industry-leading technology. Kinto introduced cutting-edge processing equipment's and a selection high-quality testing equipment to ensure that every product meets the highest Copper bus bar requirements. The R and D team and technical team have deep knowledge and experience in delivering custom solutions a range of processing needs that are complex.

Kinto always puts its focus on the customer provide superior customer service that will result in win-win development. A knowledgeable customer service team available to collect and analyze feedback from customers and ideas. This helps improve the quality of our services and products. We have Copper bus bar a long-term and good cooperative partnership many large and medium-sized enterprises at home abroad, such as Danfoss, Ballard, Methode Electronics, MARQUARDT, WEICHAl, RPS Switchgear, FLEXLINK, Mersen, ABB, SIEMENS, ChangyingXinzhi, OLIMPIA, VACON.

Copyright © Kinto Electric Co., Ltd All Rights Reserved