Ever wonder the benefits of M8 busbar technology? M8 busbars are a fabulous invention, here all the benefits you can reap with an M8 busbar.

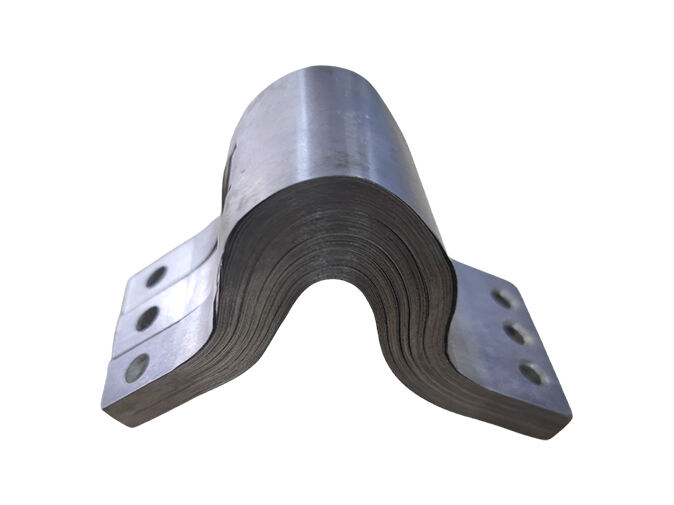

M8 Busbars - those tiny Electrical Superhereos Small metal bars with lots of holes [...] act as connectors for electrical devices. Think of them like the conductors on a train track, allowing electricity to easily move from one place to another. M8 busbars - by connecting devices easily and allowing power to switch between devices faster, M8 busbars makes it easier for us connect our device or get them powered.

The M8 busbar technology is elegant in its simplicity. Unlike the usual busbar, there is very little power loss during electrical transfer with M8 connectors which enables good energy utilization and performance. Their reliability is equally unmatched & their unyielding durability makes them the leading choice for environments where only the best will do.

In order to leverage the power of M8 busbar technology, best practices must be followed. The first and most important step in obtaining the best power rail system is to choose 1) a proper busbar size for your application. Secondly, you must also ensure that your M8 busbar system is constructed with high-quality materials to resist corrosion and extend its life. Lastly, it is a must to follow the manufacturer's installation instructions properly for your m8 busbar system functions smoothly.

The M8 busbar systems have that effect in industrial landscapes. Critical for the provision of energy power to large machinery and equipment, these systems help in improving performance levels as well as saving on costs. M8 Busbars also assist productivity with excellent power transfer, and at the same time are less costly when compared to conventional connectors thus allowing more profit by saving on operational expenses.

Consequently, M8 busbar technology comes out as a total electricity transfer game changer. These factors, along with its speedy and responsive power transfer features as well as the fact that it is highly adaptable to a variety of industrial applications make electricity very promising for serving us throughout our world. So always uphold the best practices, use quality materials and get it properly installed for your M8 busdrop system to deliver years of reliable performance.

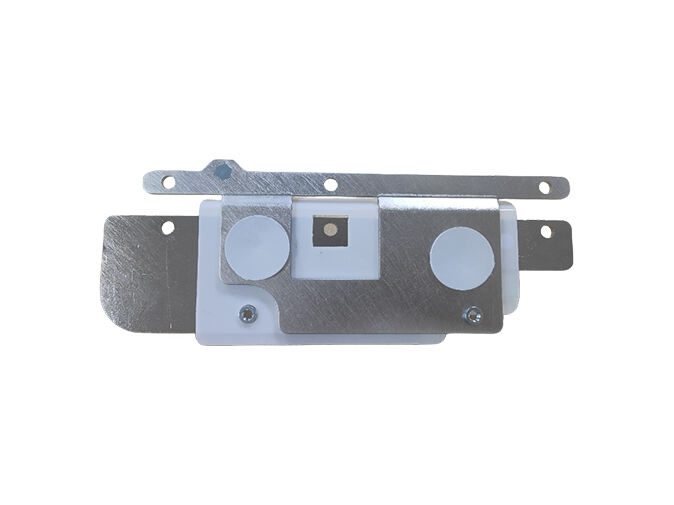

It is accredited by ISO 9001 ISO14001 as along with IATF 16949. The company controls every link the acquisition of raw materials to production process to finished product inspection to ensure stable reliable quality of its products. Additionally, it adopts a management system that is digital boost efficiency in production and improve accuracy. The management of m8 busbar drawings digitally using EDM system offers accuracy and traceability, as well as strong support for product design and production.

Kinto is top manufacturer of busbars, was founded in the year 2005. It covers an area of more than 8000 square meters. Kinto is committed to the development of new energy storage and transmission technologies along electronic appliances and communication. Kinto has a wealth of experience and industry-leading technology. Kinto introduced cutting-edge processing equipment's and a selection high-quality testing equipment to ensure that every product meets the highest m8 busbar requirements. The R and D team and technical team have deep knowledge and experience in delivering custom solutions a range of processing needs that are complex.

Kinto always places the customer first offers exceptional customer service in order to create a win-win situation. Kinto has a m8 busbar customer service department will constantly collect customer opinions well as suggestions to improve the quality of services products. We have established a long-term and good cooperative partnership with many large medium-sized enterprises at home and abroad, such as Danfoss, Ballard, Methode Electronics, MARQUARDT, WEICHAl, RPS Switchgear, FLEXLINK, Mersen, ABB, SIEMENS, ChangyingXinzhi, OLIMPIA, VACON.

Kinto is focused cost management and continuous improvement of production processes. Reduce waste in raw materials and equipment and optimize the use of equipment, in addition to other strategies, in order to achieve effective control. The quality of the raw materials costs is assured a long-term and stable relationship supplier. In addition, it continually introduces new technologies and equipment in order to enhance production efficiency quality, thereby further reducing production costs. These measures m8 busbar us offer customers more affordable prices, while also ensuring product high-quality, and to achieve ideal balance between cost control and market competitiveness.

Copyright © Kinto Electric Co., Ltd All Rights Reserved