Electricity is one of those vital things that people use on a daily basis. It enables us to, turn the lights on use computers as adverts so eloquently tells you and refrigerators keep our food cold. Most of the technology that we use everyday would never work without electricity. The electricity, however, needs to travel through wires and other materials that help it get to us before anything else. Electrolytic copper busbar might get some double-plus-good marks for that.

So just what is an electrolytic copper busbar? You have a sheet of copper which is normally flat and been specially made to conduct electricity very well. It can thus carry a lot of electrical current without overheating, or losing too much energy as heat when the electricity moves. Electrolytic copper busbars are generally used in important electrical systems due to their special properties.

The strength of an electrolytic copper busbar is a key driver in their use. So here we have a heavy metal that can take care of high temperatures and pressure without being break or damaged. It is withal quite hardy and tenacious; therefore, it lasts relics. That makes it a very attractive option for many electrical applications.

Factories which are installed with large machines and equipment that require a massive amount of power to run, electrolytic copper busbars would be very useful. For this reason, they are ideal for wiring large machines and complex systems that need a high volume of electrical power because it can transport very strong amounts of current without overheating.

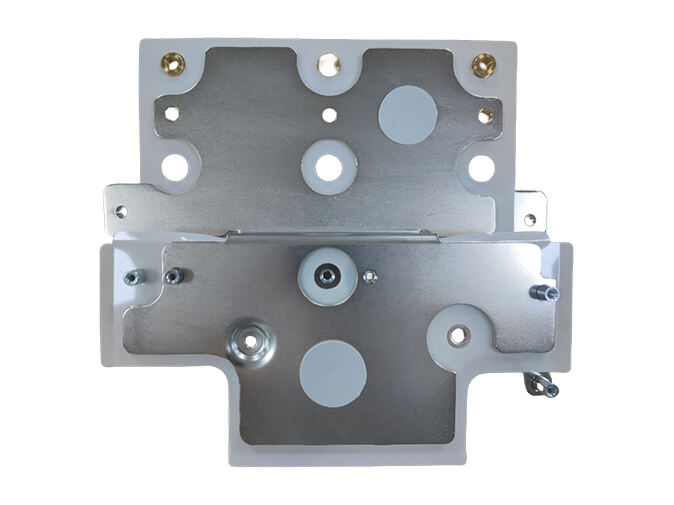

Factories use electrolytic copper busbars which can be shaped and cut in the manner of design being made. This is a flexible wiring mechanism that gives engineers the ability to develop custom wiring solutions according about their buildings and operations. For businesses, this ensures that even the most complex electrical systems in a factory are no longer an obstacle to fit electrolytic copper busbars perfectly.

This energy efficiency is important for a couple of big reasons. For one, the more wasted energy means you waste more money doing the same work. This can start to really add up and increase your electric bill. And second, the more energy we save, the better it is for all efforts to maintain a cleaner environment. Fewer greenhouse gases are made overall, making for a greener planet down the line.

Another great thing about having electrolytic copper busbars is the fact that they conduct electricity better than so many other materials. They are easily the best option on the market if you have to move a lot of power fast and efficiently. From homes to large factories, many electrical systems need electrolytic copper busbars to function properly and efficiently.

It is accredited by ISO 9001 ISO14001 as along with IATF 16949. The company controls every link the acquisition of raw materials to production process to finished product inspection to ensure stable reliable quality of its products. Additionally, it adopts a management system that is digital boost efficiency in production and improve accuracy. The management of electrolytic copper busbar drawings digitally using EDM system offers accuracy and traceability, as well as strong support for product design and production.

Kinto is focused cost management and continuous improvement of production processes. Reduce waste in raw materials and equipment and optimize the use of equipment, in addition to other strategies, in order to achieve effective control. The quality of the raw materials costs is assured a long-term and stable relationship supplier. In addition, it continually introduces new technologies and equipment in order to enhance production efficiency quality, thereby further reducing production costs. These measures electrolytic copper busbar us offer customers more affordable prices, while also ensuring product high-quality, and to achieve ideal balance between cost control and market competitiveness.

Kinto is top manufacturer of busbars, was founded in the year 2005. It covers an area of more than 8000 square meters. Kinto is committed to the development of new energy storage and transmission technologies along electronic appliances and communication. Kinto has a wealth of experience and industry-leading technology. Kinto introduced cutting-edge processing equipment's and a selection high-quality testing equipment to ensure that every product meets the highest electrolytic copper busbar requirements. The R and D team and technical team have deep knowledge and experience in delivering custom solutions a range of processing needs that are complex.

Kinto always focusing on the client providing outstanding customer service to ensure an outcome that is win-win. A professional customer service team always available to collect and analyze feedback from customers and suggestions. This helps enhance our products and services. We have established a long-term good cooperative electrolytic copper busbar with many large and medium-sized enterprises at home and abroad, such as Danfoss, Ballard, Methode Electronics, MARQUARDT, WEICHAl, RPS Switchgear, FLEXLINK, Mersen, ABB, SIEMENS, ChangyingXinzhi, OLIMPIA, VACON.

Copyright © Kinto Electric Co., Ltd All Rights Reserved