Copper bus bar is a kind of metal that has made its space in electrical solutions. Effetive Circuit: A path that allows electricity to travel along. The Copper busbar works as smooth highway for the electricity to move, like a car moves on an expressway. Why Is Copper Busbar Better Than Others? We are going to go over the pros of using copper busbar through this text, explain how it aids in Energy Management and Processing Equipment, its life expectancy as well look at why choosing copper is an economically sound decision for generating savings down the track. Most major advantages of Kinto tinned copper busbar is its capability to conduct electricity. This means it can conduct electricity very well. It is a metal that does not break easily and based on this, can last longer without renewals since light. Other than [] Load currents fa[df]it may be need due to point of mechanical behavior. If we use copper busbar to bring power all over an electrical system, this is the one way that everything in there will get what it needs so our devices work right. Whether our home appliances or even giant industrial machines.

Copper busbar is also incredibly useful for losing minimal electricity in electrical systems. Heat: This laminated copper busbar is what some of electricity can change into when it moves through the wire. When energy is wasted, as it flows through a material some of the electric potential that was in the source never makes it to where ever you tried sending. This process is called resistance. But copper has extremely low resistance, so it wastes very little energy as heat unlike other materials. They are the ones that save us energy and in return money on our electric bills. Copper busbar Being used, we can be more better and efficient in our electrical system works which is good for both of us pocket wise and even environment point of view.

Copper busbar is a high strength and durable metal. Kinto insulated copper busbar is its biggest advantage that it never rusts at all and decompose quite resisting over time. The fact that it doesn't corrode is one reason why we use it for electrical systems lasting a long time. Since the copper busbar has a longer service life and does not have to be changed for many years, our expense will also save. We do not need to purchase them new things for while allowing us to spend our money on other important areas of their life.

While saving you money on installation, Copper busbar is just as prudent an option. While copper costs a little more than other metals such as aluminum or steel, it is your best buy in the long run. This is because a copper busbar leads to greater durability, and enables energy saving. Kinto bare copper busbar can prevent you from spending in a large amount when it comes to your electricity bills as time goes on and also repairs/maintenance. Moreover, adopting copper busbar can prevent costly electrical issues and failures. Thus, your investment in copper busbar may save you arm and a leg.

Many steps are there to be followed, in the installation of copper busbar into electrical panels. 1- The busbar is first cropped with the correct dimensions to fit into the panel. It is then made clean and ready to mate well with other electrical components. Then hdhc tinned copper busbar gets mounted inside the electrical panel and connected to other wires or devices that require power. You need to selectively install them properly so that each goes through its role in bed safely. It is important to ensure that the busbar is tight and thus all of its setup secure, so you can be sure your electrical installation will perform safely over time.

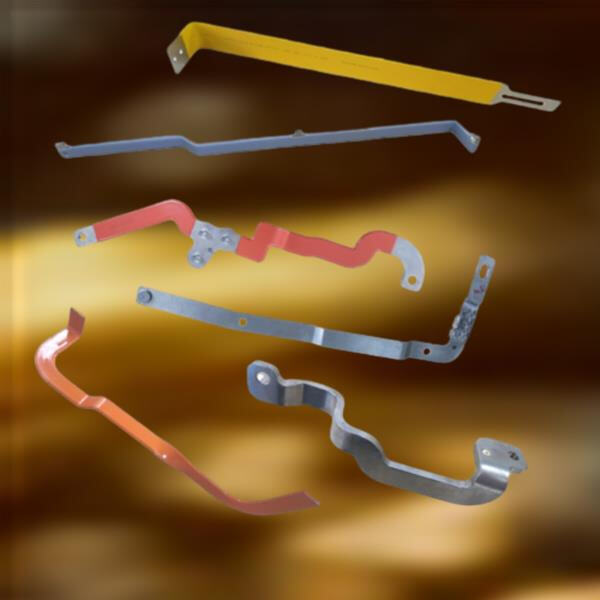

Kinto is a top busbar producer Copper busbar in 2005 covering 8000 square meters is committed to the development of new energy storage, transmission and distribution products, electronic appliances and communications featuring the latest technology and a wealth of production experience. Kinto has introduced latest processing equipment's and a variety of high-quality testing equipment to ensure that every product is in line with highest standards of quality requirements. The R and D team technical staff have extensive expertise and experience in providing customized solutions for a wide range complex processing requirement.

Kinto is constantly focusing on customers and offering superior customer service that will result in the goal of a win-win for everyone. Our professional customer service team is on hand to gather and analyze feedback from customers suggestions. This allows us to improve the Copper busbar of services and products. We have established a long-term and good cooperative partnership many large and medium-sized enterprises home and abroad, such as Danfoss, Ballard, Methode Electronics, MARQUARDT, WEICHAl, RPS Switchgear, FLEXLINK, Mersen, ABB, SIEMENS, ChangyingXinzhi, OLIMPIA, VACON.

Kinto is focused on cost control and improvement through continual optimization production processes. Reduce waste in raw materials and equipment, and improve the utilization of equipment, in addition to other methods, to attain an effective control. The long-term and steady cooperation with suppliers guarantees competitiveness of procurement costs for raw materials. In addition, it actively introduces advanced production Copper busbar equipment to improve production efficiency and quality and reduce production costs. This allows us give customers affordable prices while still ensuring high-quality, and to achieve an ideal balance between cost control market competitiveness.

It is accredited by ISO 9001 ISO14001 as along with IATF 16949. The company controls every link the acquisition of raw materials to production process to finished product inspection to ensure stable reliable quality of its products. Additionally, it adopts a management system that is digital boost efficiency in production and improve accuracy. The management of Copper busbar drawings digitally using EDM system offers accuracy and traceability, as well as strong support for product design and production.

Copyright © Kinto Electric Co., Ltd All Rights Reserved